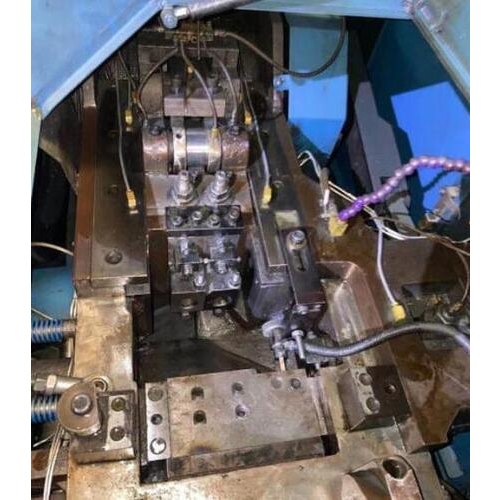

Used Taiwan HUI HONG HBF53 M5 3 Mold 3 Blow Bolt Making Machine

Price 1980 USD ($)/ Unit

Used Taiwan HUI HONG HBF53 M5 3 Mold 3 Blow Bolt Making Machine Specification

- Power

- Main Motor: 7.5 HP

- Color

- Green

- Machine Type

- 3 Mold 3 Blow Bolt Making Machine

- Feature

- High Speed, Durable, Taiwan Make

- Capacity

- M5 (Max. Bolt Diameter 5mm)

- Dimension (L*W*H)

- Approx. 4.3 x 1.7 x 2.1 meters

- Used For

- Bolt Forming, Cold Heading

- Weight

- Approx. 6000 kg

- Voltage

- 380V / 3 Phase

- Condition

- Used

- Output

- Up to 180 pieces/min (depending on size and material)

- Feeding System

- Automatic In-Feed

- Shank Diameter Range

- 2 mm to 5 mm

- Forging Station

- 3 Dies & 3 Blows

- Suitable Raw Material

- Steel, Brass, Copper

- Drive Type

- Mechanical

- Lubrication System

- Automatic Forced Lubrication

- Control System

- Manual and Semi-automatic

- Main Shaft Speed

- Up to 180 rpm

- Max Bolt Length

- 50 mm

- Cutting Method

- Automatic

- Machine Structure

- Cast Iron Body

- Safety Features

- Emergency Stop, Protective Covers

- Model

- HBF53

- Noise Level

- Medium

Used Taiwan HUI HONG HBF53 M5 3 Mold 3 Blow Bolt Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T)

- Main Export Market(s)

- Asia, South America, Middle East, North America, Eastern Europe, Western Europe, Australia, Central America, Africa

- Main Domestic Market

- All India

About Used Taiwan HUI HONG HBF53 M5 3 Mold 3 Blow Bolt Making Machine

Brand: HUI HONGCommodity unit:unit

Inventory quantity: 1

Code: 13699

(The price of the website platform is not the actual quotation, please contact us for the specific quotation according to your products and suitable machine models)

Precise and Efficient Bolt Production

Designed for high-speed and precision, the HBF53 can deliver up to 180 bolts per minute, making it suitable for mass production requirements. Its three die and three blow station setup ensures uniformity and dimensional accuracy for each bolt. The automatic feeding and forced lubrication system contribute to smooth, continuous operation and extend the machine's lifespan.

Versatile Material Handling

This machine handles a wide range of raw materials, including steel, brass, and copper, all supported by its sturdy cast iron build. With a maximum bolt length of 50 mm and a shank diameter range of 2 mm to 5 mm, manufacturers can cater to diverse bolt specifications with ease. The main shaft speed can reach up to 180 rpm, further enhancing productivity.

Safety and User-Friendly Operation

Safety is prioritized with emergency stop functions and protective covers, ensuring operator protection during use. The manual and semi-automatic control systems, combined with a noise level categorized as medium, make the HBF53 both manageable and safe for workshop environments. Routine maintenance is streamlined owing to its accessible design and automatic lubrication.

FAQ's of Used Taiwan HUI HONG HBF53 M5 3 Mold 3 Blow Bolt Making Machine:

Q: How does the HBF53 3 Mold 3 Blow Bolt Making Machine work?

A: The HBF53 operates using a cold heading process, where steel, brass, or copper rods are automatically fed into the machine. Through its three dies and three blow stations, the rod is progressively formed into the desired bolt shape. The entire process is automated from feeding to cutting, with forced lubrication keeping the system running smoothly.Q: What are the advantages of using this bolt making machine?

A: This machine offers high-speed production (up to 180 pieces/min), reliable durability due to its cast iron construction, and versatility in processing multiple raw materials. The automatic functionalities also reduce manual labor, while safety features like emergency stops and covers enhance operator security.Q: When should I consider using a 3 Mold 3 Blow Bolt Making Machine like the HBF53?

A: You should consider this machine if your facility requires bulk production of bolts with precise dimensions and consistent quality, especially when working with diameters up to 5 mm and lengths up to 50 mm. It's ideal for manufacturers, suppliers, and exporters demanding efficiency and high output.Q: Where can the HUI HONG HBF53 be installed, and what are the power requirements?

A: The HBF53 is suitable for installation in industrial workshops, manufacturing facilities, or bolt production plants. It requires a 380V, 3-phase electrical supply and is powered by a 7.5 HP main motor, making it compatible with most standard industrial power systems.Q: What maintenance and safety precautions are recommended for the HBF53?

A: Regular inspection and cleaning of the automatic lubrication and feeding systems are advised, along with checking the protective covers and emergency stop mechanisms to ensure proper function. Operators should always follow safety protocols and adhere to recommended maintenance schedules.Q: How can this machine benefit my bolt manufacturing operation?

A: Using the HBF53 can significantly boost your productivity and product quality due to its rapid operation, dimensional accuracy, and reliability. Its automated features reduce manual workload and the risk of operational errors, making your manufacturing process more efficient and cost-effective.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used Multi Station Bolt Making Machine Category

Used Taiwan 5mm 2 Mold 2 Blow Bolt Making Machine

Price 1970 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Output : Bolts (up to 5mm diameter)

Condition : Used

Voltage : 380 V, 3 phase

Machine Type : 2 Mold 2 Blow Bolt Making Machine

Used Japan Asahi Okuma AOT-4XL 2 Mold 2 Blow Bolt Making Machine

Price 1980 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Output : Bolts from M6 to M14; Length up to 120mm

Condition : Used

Voltage : 3 Phase, 220/380V

Machine Type : Bolt Making Machine

Used Taiwan CHUNZU CDH-52 5mm 2 Mold 2 Blow Bolt Making Machine

Price 1985 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Output : Finished bolts (max. 5mm)

Condition : Used

Voltage : 380V / 3 Phase

Machine Type : Bolt Making Machine

Used Taiwan HUI HONG 5mm 3-Mold 3-Blow Bolt Making Machine

Price 1985 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Output : Bolts up to 5mm diameter

Condition : Used

Voltage : 380V / 50Hz

Machine Type : Bolt Making Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry