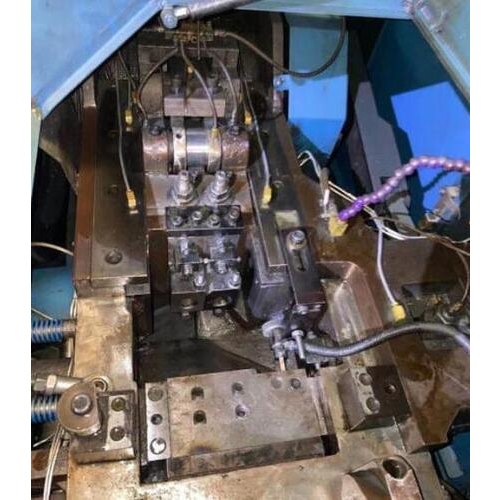

Used Taiwan 5mm 2 Mold 2 Blow Bolt Making Machine

Price 1970 USD ($)/ Unit

Used Taiwan 5mm 2 Mold 2 Blow Bolt Making Machine Specification

- Capacity

- Up to 120 pieces/min (depending on bolt size)

- Feature

- High-speed production, efficient operation, robust construction

- Power

- Approx. 6.5 kW

- Machine Type

- 2 Mold 2 Blow Bolt Making Machine

- Color

- Standard industrial green

- Weight

- Approx. 1800 kg

- Used For

- Producing bolts up to 5mm diameter

- Manufacturing Year

- NA (Used Machine)

- Condition

- Used

- Dimension (L*W*H)

- Approx. 2800 mm x 1100 mm x 1500 mm

- Voltage

- 380 V, 3 phase

- Output

- Bolts (up to 5mm diameter)

- Mold Station

- 2 Mold

- Die Opening

- 5mm maximum

- Lubrication System

- Centralized automatic lubrication

- Maintenance

- Regular basic maintenance required

- Machine Structure

- Heavy duty cast frame

- Stroke Length

- Standard (suitable for small to medium bolts)

- Ram Diameter

- Standard 5mm class

- Noise Level

- Within standard industrial limits

- Spare Parts Availability

- Available for Taiwanese machines

- Blow Station

- 2 Blow

- Control System

- Manual/Basic Electrical Controls

- Operator Requirement

- 1 skilled operator per shift

Used Taiwan 5mm 2 Mold 2 Blow Bolt Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T)

- Main Export Market(s)

- Asia, South America, Middle East, Eastern Europe, Africa, Western Europe, Central America, Australia, North America

- Main Domestic Market

- All India

About Used Taiwan 5mm 2 Mold 2 Blow Bolt Making Machine

Brand: Made in TaiwanCommodity unit:unit

Inventory quantity: 1

Code: 10848

(The price of the website platform is not the actual quotation, please contact us for the specific quotation according to your products and suitable machine models)

Efficient Bolt Production

A dual mold, dual blow system enables this machine to produce bolts rapidly, with a capacity of up to 120 pieces per minute based on bolt size. It's engineered for continuous operation and delivers consistent, precise results within industrial noise standards.

Robust and Reliable Construction

Built on a heavy-duty cast frame, this machine promises lasting durability even in demanding manufacturing environments. The centralized automatic lubrication system enhances reliability, minimizing wear and ensuring smooth cycles with less frequent manual intervention.

Ease of Operation and Maintenance

Requiring only one skilled operator per shift, this bolt making machine is designed for straightforward control with basic electrical options. Regular maintenance helps sustain peak performance, and spare parts are easily accessible for Taiwanese equipment, reducing potential downtime.

FAQ's of Used Taiwan 5mm 2 Mold 2 Blow Bolt Making Machine:

Q: How does the 2 mold 2 blow configuration improve bolt production efficiency?

A: The dual mold and dual blow stations allow simultaneous forming and blowing steps, which increases cycle speed and enables the machine to produce more bolts per minute compared to single-stage models.Q: What types of bolts can this machine produce, and what is the maximum diameter?

A: This machine is specifically used for manufacturing bolts with a maximum diameter of 5mm, making it suitable for producing small to medium-sized bolts efficiently.Q: When is regular maintenance recommended for this machine?

A: Basic regular maintenance is required to ensure continued reliable operation. It is advised to follow a scheduled routine based on usage, typically involving daily checks and periodic lubrication system inspections.Q: Where can I source spare parts for this used Taiwanese bolt making machine?

A: Spare parts for this model are readily available through suppliers specializing in Taiwanese machinery, which helps ensure minimal downtime and easy replacements.Q: What is the operation process for this bolt making machine?

A: The process involves feeding raw material, which is formed into bolts using two molding stages followed by two blowing stages, guided by manual or basic electrical controls and enhanced by a centralized automatic lubrication system.Q: How many operators are required per shift to run this machine efficiently?

A: Only one skilled operator is needed per shift to oversee the full operation, owing to the machine's user-friendly control system and automated features.Q: What are the main benefits of using this used 2 mold 2 blow machine?

A: The key advantages include high-speed production, robust and durable construction, efficient operation, reduced manual labor requirements, reliable part availability, and compliance with industrial noise standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used Multi Station Bolt Making Machine Category

Used Taiwan CHUNZU CPF 035 M3 5 Mold 5 Blow Bolt Making Machine

Price 1986 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power : Approx. 11 kW

Condition : Used

Feature : 5 Mold 5 Blow, High Speed Production

Machine Type : Bolt Making Machine

Used Korea CH0322 2 Mold 2 Blow Bolt Making Machine

Price 1999 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power : 7.5 kW

Condition : Used

Feature : 2 Mold 2 Blow Design

Machine Type : 2 Mold 2 Blow Bolt Making Machine

Used Taiwan UQueen FMB3310 3 Mold 3 Blow Bolt Making Machine

Price 1970 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power : 11 kW Main Motor

Condition : Used

Feature : High precision forming, Automatic operation

Machine Type : 3 Mold 3 Blow Bolt Making Machine

Used Taiwan HUI HONG 5mm 3-Mold 3-Blow Bolt Making Machine

Price 1985 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Power : Approx. 7.5 kW

Condition : Used

Feature : 3Mold 3Blow mechanism for efficient cold heading

Machine Type : Bolt Making Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry