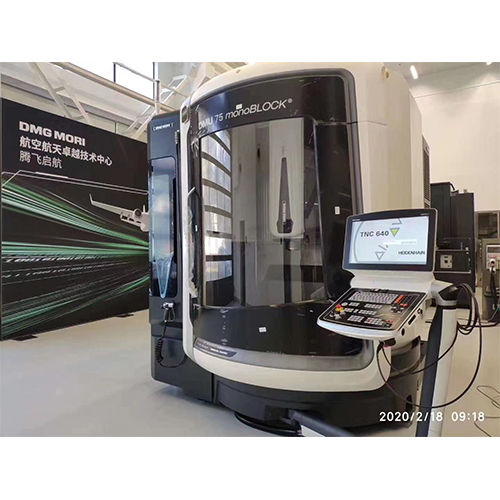

Demaji DMU75 mono block five axis machining center

Demaji DMU75 mono block five axis machining center Specification

- Output

- CNC milled components

- Manufacturing Year

- 2022

- Feature

- MonoBLOCK design, simultaneous 5-axis machining

- Weight

- 11000 kg

- Color

- White/Grey

- Dimension (L*W*H)

- 3250 mm x 2200 mm x 2900 mm

- Voltage

- 400 V

- Capacity

- 750 mm worktable, 600 kg max table load

- Used For

- Precision metal component machining

- Condition

- New

- Power

- 38 kW

- Machine Type

- Five Axis Machining Center

- Axis Travel (X/Y/Z)

- 750/650/560 mm

- Repeatability

- 1 m

- Control System

- Heidenhain TNC 640

- Chip Removal

- Automatic chip conveyor

- Rotary Table Diameter

- 650 mm

- Cooling System

- Integrated coolant system

- Tool Magazine Capacity

- 60 tools

- Lubrication System

- Centralized automatic lubrication

- Interface

- Ethernet, USB

- Rapid Traverse Rate

- 50 m/min

- Spindle Speed

- 21000 rpm (max)

- Positioning Accuracy

- 2.5 m

Demaji DMU75 mono block five axis machining center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Demaji DMU75 mono block five axis machining center

DMU75 Mono Block Five Axis Machining Center-Features and Applications

The Demaji DMU75 is engineered for high-precision metal machining, featuring a meritorious monoBLOCK design and a capacity for 750 mm workpieces. Potent features include a 60-tool magazine, integrated coolant system, and automatic chip removal. Its preeminent simultaneous 5-axis machining enables intricate component production. Commercially, it's ideal for automotive, aerospace, and mold industries, delivering precision with each cycle thanks to high repeatability and positioning accuracy. This model is favored by industry experts looking for reliable performance.

Export Market, Supply Ability, and Order Fulfillment

We offer the Demaji DMU75 at competitive rates to main export markets, including Europe, North America, and Southeast Asia. Our ample supply ability ensures prompt order completion and tailored solutions. Each machine is securely packaged in robust wooden crates for safe international shipping. Contact us to receive an exclusive offer, check the current rate, and discuss your project timeline. Our dedicated team ensures streamlined logistics for smooth delivery and after-sales support.

FAQ's of Demaji DMU75 mono block five axis machining center:

Q: How does the Demaji DMU75 ensure precision in machining operations?

A: The DMU75 integrates the Heidenhain TNC 640 control system and features positioning accuracy of 2.5 m and repeatability of 1 m, ensuring consistent and precise metal component production.Q: What are the commercial applications of this five axis machining center?

A: This machining center is widely used in the manufacture of high-precision metal components for the automotive, aerospace, and mold industries due to its simultaneous 5-axis capabilities and robust design.Q: When can customers expect delivery after placing an order?

A: Order completion and delivery timelines depend on current availability, but our high supply ability ensures prompt fulfillment, with specific timelines communicated at the time of purchase.Q: Where is the Demaji DMU75 manufactured and supplied from?

A: This advanced machining center is manufactured in China and supplied globally through a network of experienced distributors, exporters, and suppliers.Q: What benefits does the monoBLOCK design offer users?

A: The monoBLOCK construction delivers enhanced machine stability, reduces vibration, and supports greater workpiece weight, contributing to exceptional machining accuracy and reliability.Q: How does the integrated coolant and automatic chip conveyor system enhance usage?

A: These features support efficient operation by managing heat and removing chips, which preserves tool life and maintains optimal machining conditions throughout production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

DMU 200P Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Machine Type : Five Axis Machining Center

Power : 62 kVA

Condition : Excellent

Used For : Highprecision milling and machining of complex parts

Feature : Simultaneous 5axis machining, high rigidity, large work envelope

DMU 60 monoblock

Minimum Order Quantity : 1 Unit

Machine Type : 5Axis CNC Universal Milling Machine

Power : 18 kW spindle motor

Condition : Used

Used For : Precision metal cutting, milling of complex components

Feature : Monoblock design, high rigidity, versatile 5axis machining

DMU 160P duoblock

Minimum Order Quantity : 1 Unit

Machine Type : DMU 160P duoblock

Power : 62 kVA

Condition : Used

Used For : Highprecision machining, 5axis milling

Feature : Universal milling, CNCcontrolled, high torque, robust design, duoblock construction

DMC 75 Vlinear Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Machine Type : Five Axis Machining Center

Power : 40 kW

Condition : Used

Used For : Highprecision machining of complex parts

Feature : Linear motor drives in all axes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry