Germany DMU 125p Five-axis Machining Center

Germany DMU 125p Five-axis Machining Center Specification

- Used For

- Precision Milling, Drilling, and Multi-axis Machining Operations

- Feature

- High Precision, Versatile Machining Capabilities, CNC Controlled, Large Work Envelope

- Dimension (L*W*H)

- 5800 x 4050 x 3400 mm

- Capacity

- Table Load Capacity up to 2,000 kg

- Machine Type

- Five-axis Machining Center

- Output

- High Productivity Multi-axis Machining

- Condition

- Used

- Power

- 60 kVA

- Weight

- Approximately 13,000 kg

- Voltage

- 400 V

- Color

- White / Grey

- Coolant System

- Integrated High-Pressure Coolant

- Spindle Speed

- Up to 18,000 rpm

- Chip Conveyor

- Included

- Z-Axis Travel

- 1000 mm

- Air Supply Requirement

- 6 bar minimum

- Y-Axis Travel

- 1000 mm

- A Axis (Swivel Range)

- +/- 120°

- X-Axis Travel

- 1250 mm

- Rapid Traverse Rate

- Up to 50 m/min

- Maximum Workpiece Height

- 1000 mm

- C Axis (Rotation Range)

- 360°

- Positioning Accuracy

- ± 0.005 mm

- Control System

- Heidenhain CNC

- Table Size

- 1250 mm x 1000 mm

- Tool Magazine Capacity

- Up to 60 Tools

Germany DMU 125p Five-axis Machining Center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Germany DMU 125p Five-axis Machining Center

Versatile Multi-Axis Machining for High Precision Applications

The Germany DMU 125p Five-axis Machining Center stands out for its advanced usage in demanding manufacturing environments. Suitable for precision milling, drilling, and multi-axis machining operations, it accommodates large workpieces with its spacious table and impressive travel axes. Its application shines in sectors requiring accurate, reliable, and flexible machining solutions, operated effortlessly through CNC programming for consistent output and exceptional workmanship.

Payment Flexibility, Secure Packaging & Reliable Supply

Enjoy competitive sale prices and streamlined order completion with the Germany DMU 125p, designed for seamless market transactions. Packaging details prioritize equipment safety, ensuring your investment arrives in flawless condition. With robust supply ability, prompt distributor support, and international export capacity, you can access this state-of-the-art machine without delay, making it an outstanding solution with strong market value for your production needs.

FAQ's of Germany DMU 125p Five-axis Machining Center:

Q: How does the Germany DMU 125p enhance precision in multi-axis machining?

A: The DMU 125p is engineered with Heidenhain CNC control and a positioning accuracy of 0.005 mm, ensuring impeccable results for precision milling and multi-axis operations.Q: What types of manufacturing industries benefit most from this machine?

A: Industries focusing on precision engineering, aerospace, automotive, and heavy machinery benefit from its large work envelope, high productivity, and versatile milling capabilities.Q: When is the optimal time to reserve or purchase this machining center?

A: It is recommended to reserve or add to cart as soon as your production demands match its high precision capabilities, especially when seeking an upgrade to large format, multi-axis CNC machining.Q: Where can this machining center be installed considering its weight and dimensions?

A: The DMU 125p, weighing approximately 13,000 kg with dimensions of 5800 x 4050 x 3400 mm, should be installed in facilities equipped with strong foundations and spacious layouts.Q: What is the process for placing an order and securing delivery?

A: Place an order by contacting the distributor, exporter, or supplier. Upon order completion, the machine is securely packaged and shipped, ensuring safe delivery to your facility.Q: How does the integrated coolant and chip conveyor system benefit operators?

A: The high-pressure coolant system and integrated chip conveyor ensure efficient cooling, clean machining environments, and reduced downtime for maintenance, improving overall productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

Makino S33-5XA

Minimum Order Quantity : 1 Unit

Condition : Used

Output : Highprecision machined metal components

Capacity : Workpiece size up to 700 mm x 500 mm x 450 mm

Machine Type : Makino S335XA CNC Vertical Machining Center

Dimension (L*W*H) : 3,000 mm x 2,500 mm x 3,150 mm

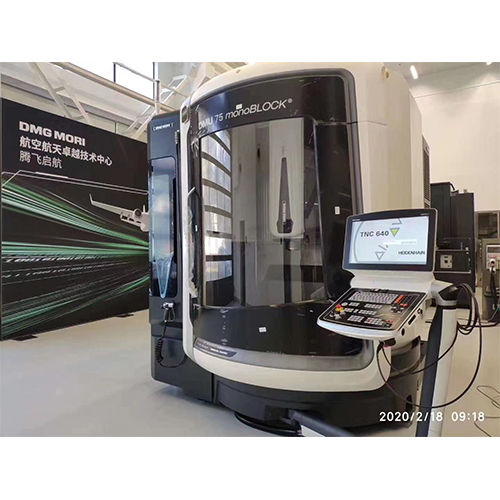

Demaji DMU75 mono block five axis machining center

Minimum Order Quantity : 1 Unit

Condition : New

Output : CNC milled components

Capacity : 750 mm worktable, 600 kg max table load

Machine Type : Five Axis Machining Center

Dimension (L*W*H) : 3250 mm x 2200 mm x 2900 mm

Fidia K199 Five Axis Linkage High Speed Vertical Machining Center

Minimum Order Quantity : 1 Unit

Condition : Used

Output : Up to 30,000 rpm spindle speed

Capacity : Max Workpiece 3200 Kg

Machine Type : Five Axis Linkage High Speed Vertical Machining Center

Dimension (L*W*H) : 4500 x 3200 x 3100 mm

DMU 50 Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Condition : Used

Output : Highspeed Machining Output

Capacity : Max Workpiece Diameter 650 mm

Machine Type : Five Axis Machining Center

Dimension (L*W*H) : 2630 x 2500 x 2250 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry