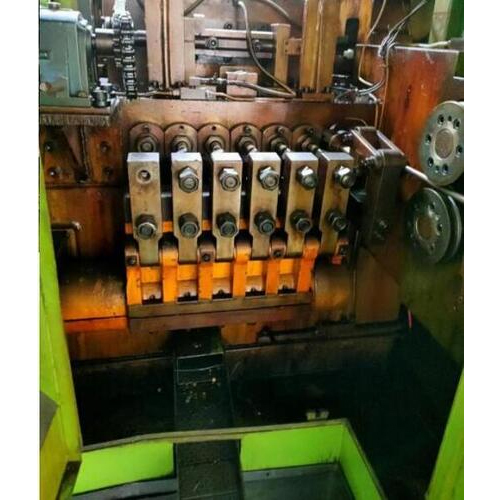

Used Taiwan BIAULI NF-8B5SL 5 Mold 5 Blow Lenthening Nut Making Machine

Price 1980 USD ($)/ Unit

Used Taiwan BIAULI NF-8B5SL 5 Mold 5 Blow Lenthening Nut Making Machine Specification

- Capacity

- Up to 160 pieces per minute (approximate)

- Weight

- Approx. 8,500 kg

- Color

- Green

- Used For

- Nut forming and manufacturing

- Output

- Nut blanks, especially lenthened types

- Machine Type

- 5 Mold 5 Blow Lenthening Nut Making Machine

- Feature

- 5-die 5-blow for making longer nuts, high precision, heavy duty

- Power

- Approx. 22 kW

- Condition

- Used

- Voltage

- 380V / 3 Phase

- Dimension (L*W*H)

- Approximately 4800 x 1900 x 2200 mm

- Control System

- Conventional electrical controls

- Lubrication System

- Centralized automatic lubricator

- Speed Adjustability

- Variable speed drive available

- Country of Original Manufacture

- Taiwan

- Stroke Length

- 110 mm

- Production Material

- Steelalloy, carbon, stainless, or brass

- Noise Level

- Standard industrial

- Application Industry

- Automotive, construction, hardware fasteners

- Workpiece Length Range

- Up to 70 mm

- Model

- NF-8B5SL

- Feeding System

- Automatic bar feeder

- Minimum Order

- 1 unit (used equipment)

- Workpiece Diameter Range

- M8 (metric 8mm)

Used Taiwan BIAULI NF-8B5SL 5 Mold 5 Blow Lenthening Nut Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Telegraphic Transfer (T/T)

- Main Export Market(s)

- Asia, South America, Middle East, Central America, Australia, North America, Africa, Eastern Europe, Western Europe

- Main Domestic Market

- All India

About Used Taiwan BIAULI NF-8B5SL 5 Mold 5 Blow Lenthening Nut Making Machine

Brand: Taiwan BIAULICode: 12582

Commodity unit:

Inventory quantity: 1

(The price of the website platform is not the actual quotation, please contact us for the specific quotation according to your products and suitable machine models)

High Efficiency Nut Manufacturing

The BIAULI NF-8B5SL machine employs a robust 5-mold, 5-blow precision forming process capable of producing up to 160 elongated nut blanks per minute. Its automatic bar feeder and centralized lubrication ensure seamless, efficient production ideal for industries with high demand.

Versatile Material Compatibility

This used machine skillfully processes a diverse range of materials including carbon steel, alloy steel, stainless steel, and brass. This adaptability makes it suitable for a variety of sectors such as automotive, construction, and general hardware manufacturing.

User-Friendly Controls and Maintenance

The NF-8B5SL features conventional electrical controls for straightforward operation. Its centralized automatic lubrication system reduces maintenance, helping businesses minimize downtime and keep production on schedule-ideal for used equipment users.

FAQ's of Used Taiwan BIAULI NF-8B5SL 5 Mold 5 Blow Lenthening Nut Making Machine:

Q: How does the BIAULI NF-8B5SL machine form elongated nuts?

A: The NF-8B5SL utilizes a five-die, five-blow forming system that progressively shapes steel, alloy, or brass bar stock into precise and elongated nut blanks. Automatic feeding and precise stroke handling ensure consistency in every part.Q: What types of industries can benefit from this nut making machine?

A: Industries such as automotive, construction, and hardware fastener manufacturing can benefit significantly due to the machine's capability to produce high volumes of strong, precisely formed nuts.Q: When should I consider using a used nut making machine like this?

A: A used machine is a cost-effective solution for manufacturers looking to expand or update production capabilities without incurring the expense of brand-new equipment, provided it's in good working condition.Q: Where can the BIAULI NF-8B5SL be installed?

A: With dimensions of approximately 4800 x 1900 x 2200 mm and a weight of about 8,500 kg, this machine requires a solid, spacious industrial floor with 380V/3-phase power supply, typically found in manufacturing plants or workshops.Q: What is the production process using this machine?

A: The process involves automatic feeding of material bars, which are then sequentially formed by the five molds and blows, lubricated centrally, and ejected as nut blanks, especially suited for longer-length nuts.Q: How is speed adjusted and controlled during operation?

A: The NF-8B5SL features a variable speed drive which allows operators to control the production rate up to approximately 160 pieces per minute, adapting to different production needs.Q: What benefits does the centralized lubrication system offer?

A: Centralized automatic lubrication ensures all critical parts receive consistent oiling, greatly reducing wear and extending the machine's operational lifespan, thus minimizing maintenance and downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Used Multi Station Nut Making Machine Category

Used Taiwan BIING FENG 19B6S 6 Mold 6 Blow Nut Making Machine

Price 2020 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Capacity : 300 pcs/min

Weight : Approx. 10,800 kg

Color : Green

Machine Type : Automatic Nut Making Machine

Used Taiwan BIING FENG BF-NF-11B5S M6 5 Mold 5 Blow Nut Making Machine

Price 1970 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Capacity : Up to 100 pieces/minute (varies by nut size)

Weight : Approx. 8000 kg

Color : Green

Machine Type : Nut Making Machine

Used Taiwan BIING FENG 12B6S 6 Mold 6 Blow Nut Making Machine

Price 1960 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Capacity : Up to 180 pieces/minute (depending on nut size)

Weight : Approx. 13,000 kg

Color : Factory Standard / Green

Machine Type : Nut Making Machine, 6 Mold 6 Blow

Used Taiwan STAMPO SNF19B6SL 6 Mold 6 Blow Lenthening Nut Making Machine

Price 1985 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Capacity : Depends on nut size; up to 150 pieces/minute

Weight : Approx. 17 Tons

Color : Green

Machine Type : 6 Mold 6 Blow Lenthening Nut Making Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry