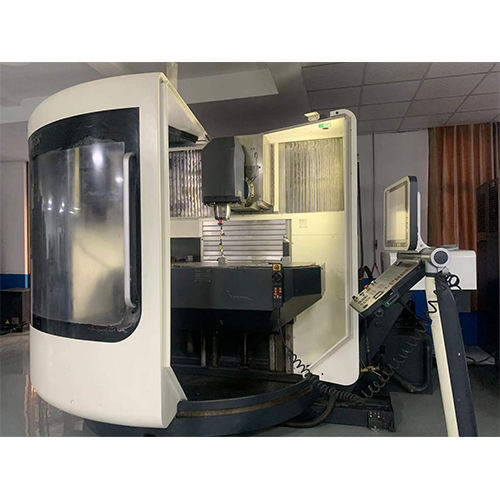

DMU 100monoBLOCK Five Axis Machining Center

DMU 100monoBLOCK Five Axis Machining Center Specification

- Used For

- Precision machining of complex parts

- Condition

- Used

- Manufacturing Year

- nan

- Dimension (L*W*H)

- 3500 x 2700 x 3200 mm

- Feature

- monoBLOCK design for optimal rigidity, simultaneous 5-axis machining

- Power

- 50 kVA

- Weight

- 16000 kg

- Color

- White / Grey

- Machine Type

- Five Axis Machining Center

- Output

- High-precision, multi-sided part production

- Voltage

- 400 V

- Capacity

- 1000 x 850 x 650 mm (X/Y/Z travel)

- Automatic Tool Changer

- Standard

- Max. X-Axis Travel

- 1100 mm

- Air Requirement

- Minimum 6 bar

- Max. Y-Axis Travel

- 850 mm

- Positioning Accuracy

- 0.008 mm

- Enclosure

- Fully enclosed working area

- Table Diameter

- 1000 mm

- Max. Table Load

- 1,000 kg

- Tool Magazine Capacity

- 60+1 positions

- Max. Z-Axis Travel

- 850 mm

- Rapid Traverse Rate

- 60 m/min

- Spindle Speed

- Up to 12,000 rpm

- Coolant System

- Through-spindle coolant system

- Chip Conveyor

- Included

- Control System

- Heidenhain iTNC 640

DMU 100monoBLOCK Five Axis Machining Center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About DMU 100monoBLOCK Five Axis Machining Center

Premier Advantages and Application Surface

The DMU 100monoBLOCK Five Axis Machining Center stands out with its monoBLOCK design, ensuring optimal rigidity for demanding industrial applications. Its primary competitive advantage is simultaneous five-axis machining, facilitating the precision manufacturing of complex parts on diverse surfaces. Used for intricate aerospace, automotive, and medical components, it delivers high output and superior accuracy, making it a preferred solution for advanced part production in various sectors.

FOB Port, Main Markets, and Supply Logistics

The DMU 100monoBLOCK ships via major FOB ports in China, arriving seamlessly to your location through efficient logistics. Serving the main domestic market as well as international destinations, our distributor network guarantees ample supply ability at the industrys lowest price points. With swift arrival and outstanding supply reliability, clients can trust our logistics expertise for prompt and secure delivery, regardless of demand volume.

FAQs of DMU 100monoBLOCK Five Axis Machining Center:

Q: How does the DMU 100monoBLOCK enhance precision machining?

A: The DMU 100monoBLOCK features simultaneous five-axis movement and a robust monoBLOCK design, enabling superior surface quality and positional accuracy for complex part machining.Q: What are the main benefits of the through-spindle coolant system?

A: The through-spindle coolant system ensures optimal cooling during operation, extending tool life, improving surface finish, and maintaining consistent machining accuracy even during demanding tasks.Q: Where can the DMU 100monoBLOCK be used?

A: It is ideally used in advanced manufacturing environments such as aerospace, automotive, and medical industries where high precision and complex part geometry are essential.Q: When can I expect delivery after placing an order?

A: Delivery typically depends on logistics arrangements from Chinas main FOB ports. After confirmation, arrival is prompt, facilitated by our streamlined supply network for minimal wait times.Q: What is the process for ordering and installing the DMU 100monoBLOCK?

A: Ordering is seamless through our distributor or supplier channels. Installation support and technical guidance are provided to ensure quick setup and optimal performance after arrival.Q: How many tools does the magazine on this machining center accommodate?

A: The DMU 100monoBLOCKs tool magazine supports 60+1 positions, allowing versatile and efficient operations during multi-sided part production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

VARIAXIS i-700 Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Manufacturing Year : 2023

Feature : Simultaneous 5axis control, Highspeed spindle, Automatic tool changer

Dimension (L*W*H) : 2,850 x 3,850 x 3,100 mm

Condition : New

Used For : Precision 5axis machining of complex components

DMC 75 Vlinear Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Manufacturing Year : 2019

Feature : Linear motor drives in all axes

Dimension (L*W*H) : 4500 x 2800 x 2950 mm

Condition : Used

Used For : Highprecision machining of complex parts

DMU70eVo linear

Minimum Order Quantity : 1 Unit

Manufacturing Year : 2011

Feature : Linear Drives, 5Axis Simultaneous Machining, High Spindle Speed, Rigid Construction

Dimension (L*W*H) : 3,000 x 2,800 x 2,900 mm

Condition : Used

Used For : Precision Machining and Milling of Metals and Alloys

Hermle C50U Five Axis Maching Center

Minimum Order Quantity : 1 Unit

Manufacturing Year : 2012

Feature : Simultaneous 5axis machining, High rigidity construction, Large working area, Advanced CNC controls

Dimension (L*W*H) : 7,000 x 6,600 x 4,850 mm

Condition : Used

Used For : Precision metal machining, aerospace, medical, and mold making industries

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry