Germany Hammer C42U Five Axis Machining Center

Germany Hammer C42U Five Axis Machining Center Specification

- Weight

- 10800 kg

- Voltage

- 400 V

- Machine Type

- Five Axis Machining Center

- Condition

- New

- Dimension (L*W*H)

- 4350 mm x 3215 mm x 3030 mm

- Manufacturing Year

- 2022

- Capacity

- Max. workpiece size 850 mm x 1000 mm x 700 mm

- Output

- Motor output 36 kW

- Used For

- High precision milling, drilling, and machining of metal components

- Color

- Industrial Grey

- Feature

- Simultaneous 5-axis machining, high rigidity structure, advanced control system

- Power

- Nominal power 36 kW

- Number of Tool Positions

- 60-station automatic tool changer

- Safety Features

- Full enclosure, safety glass doors, CE certification

- Ambient Temperature Range

- 15°C to 40°C

- Spindle Speed

- Maximum 18,000 rpm

- Chip Removal

- Integrated chip conveyor and coolant filtration

- Table Load Capacity

- Up to 1,200 kg

- Linear Guides

- Preloaded roller guides for all axes

- Control System

- Heidenhain TNC 640

- Noise Level

- < 78 dB(A)

- Tool Holder

- HSK63A

- Coolant Supply

- Internal and external coolant system

- Rotary Table Diameter

- 650 mm

- Lubrication

- Automatic centralized lubrication system

- Axis Travel (X/Y/Z)

- 800 mm / 1,000 mm / 700 mm

- Drive Type

- Direct drive for main spindle and rotary axes

Germany Hammer C42U Five Axis Machining Center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Germany Hammer C42U Five Axis Machining Center

Cutting-Edge Application and Machine Features

Engineered for high-precision milling, drilling, and machining of diverse metal components, the Germany Hammer C42U excels in environments requiring simultaneous five-axis operation. Special features include a preloaded roller guide system, comprehensive safety enclosure, and centralized lubrication. The machine's robust construction, generous table load capacity, and advanced rotary table make it indispensable for manufacturers demanding versatility and reliability in their production media.

Secure FOB Port & Export Market Logistics

Germany Hammer C42U Five Axis Machining Center is securely shipped from China's prominent FOB ports to main export markets worldwide, including Europe, Asia, and the Americas. Exporters and traders benefit from established shipping processes ensuring safe, timely delivery of shipped goods. Flexible payment terms are available to enhance trading confidence and partner satisfaction, underscoring a commitment to seamless international business.

FAQ's of Germany Hammer C42U Five Axis Machining Center:

Q: How does the Germany Hammer C42U ensure high machining precision?

A: The C42U achieves high precision through simultaneous five-axis machining, advanced Heidenhain TNC 640 control, preloaded roller guides, and a highly rigid structure, enabling superior accuracy in complex metal component fabrication.Q: What are the standout features of the C42U Five Axis Machining Center?

A: Key features include a 60-station automatic tool changer, direct drive spindle for up to 18,000 rpm, industrial-grade full enclosure, advanced coolant systems, and both internal and external lubrication. These ensure efficient, safe, and versatile operation.Q: Where is the Germany Hammer C42U typically exported from and to which markets?

A: The machine is distributed, exported, and supplied from China's major ports to various main export markets across Europe, Asia, Americas, and other industrialized regions.Q: What is the process for safe shipping and delivery of the C42U?

A: All machines are securely packed and transported under stringent shipping standards to ensure goods arrive safely. Comprehensive logistics management tracks the status of each shipment throughout export and delivery.Q: Who benefits from using the Germany Hammer C42U?

A: Manufacturers, exporters, and metal fabrication specialists benefit from its laureate-level capability, improved cycle times, reliability, and praiseworthy performance in demanding production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

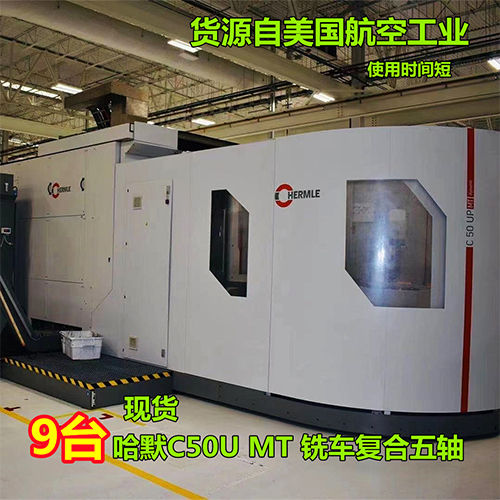

German Hermle C50U MT

Minimum Order Quantity : 1 Unit

Voltage : 400 V, 50 Hz

Dimension (L*W*H) : Approx. 7300 mm x 5550 mm x 3620 mm

Condition : Used, Excellent

Machine Type : 5Axis CNC Machining Center with Turning (MillTurn)

Weight : Approx. 28,000 kg

Fidia K199 Five Axis Linkage High Speed Vertical Machining Center

Minimum Order Quantity : 1 Unit

Voltage : 400 V

Dimension (L*W*H) : 4500 x 3200 x 3100 mm

Condition : Used

Machine Type : Five Axis Linkage High Speed Vertical Machining Center

Weight : 21000 kg

Germany DMU200P

Minimum Order Quantity : 1 Unit

Voltage : 400 V

Dimension (L*W*H) : 5500 mm x 4500 mm x 3100 mm

Condition : Used, Excellent Condition

Machine Type : CNC Universal Milling Machine

Weight : Approximately 18,000 kg

DMU 210P-2009 Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Voltage : 400 V, 50 Hz

Dimension (L*W*H) : 8100 mm x 5500 mm x 3800 mm (approx.)

Condition : Used

Machine Type : Five Axis Machining Center

Weight : Approximately 35,000 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry