DMU 210P

DMU 210P Specification

- Used For

- Precision Milling and Machining

- Capacity

- Heavy duty, Large size workpieces

- Manufacturing Year

- 2012

- Color

- Grey

- Condition

- Used

- Power

- 55 kW

- Machine Type

- Vertical Machining Center

- Feature

- High speed, versatile, rigid construction

- Output

- High accuracy finished components

- Dimension (L*W*H)

- 6800 x 3700 x 3150 mm

- Voltage

- 400 V

- Weight

- 23000 Kg

- Spindle Taper

- ISO 50

- Max Table Load

- 6500 kg

- Y Axis Travel

- 2100 mm

- Z Axis Travel

- 1250 mm

- Chip Conveyor

- Yes

- Tool Magazine Capacity

- 60 tools

- X Axis Travel

- 2100 mm

- Controller

- Heidenhain iTNC 530

- CNC System

- Heidenhain

- Coolant System

- Yes

- Spindle Speed Range

- 20 - 8,000 rpm

- Rapid Traverse Rate

- 60 m/min (X/Y/Z)

- Table Size

- 1800 x 2100 mm

DMU 210P Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About DMU 210P

Versatile Utility and Features of DMU 210P

The DMU 210P is widely used for precision milling, machining, and high-speed manufacturing tasks. Its rigid construction ensures stability and accuracy, even for heavy-duty and large-sized workpieces. With advanced cooling and chip management systems, this vertical machining center is ideal both for specialized and general-use manufacturing environments. Its high-speed operation and broad tooling capacity enable efficient production, making it an asset for industries demanding versatility, robustness, and exceptional component finish.

Sample Policy, Proposal, and Timely Delivery

Formal quotations are provided upon proposal amount confirmation. Sample requests are entertained based on agreement conditions. Once an order is placed, the arrival and dispatch schedule is swiftly communicated-ensuring precise planning. Packaging details guarantee robust protection, with each unit securely packed for both domestic and international delivery. Efficient packing and careful dispatch procedures safeguard the pristine condition of your DMU 210P upon arrival, enabling immediate installation and operation with minimal delay.

FAQ's of DMU 210P:

Q: How does the DMU 210P ensure high-precision milling operations?

A: The DMU 210P features a Heidenhain iTNC 530 CNC controller, rigid construction, and a comprehensive coolant system, enabling stable and precise machining, even for large or heavy workpieces.Q: What is the process for ordering and receiving the DMU 210P?

A: Once you finalize the proposal amount, we provide a formal quote. After order confirmation, we arrange secure packing and timely dispatch, sharing arrival details for seamless installation at your facility.Q: When is sample availability discussed for the DMU 210P?

A: Sample policies and availability are reviewed upon inquiry. Arrangements for sample provision may be possible as per mutual agreement and proposal discussion.Q: What benefits does the DMU 210P offer for large-scale manufacturing?

A: Its expansive table size, large tool magazine, rapid traverse rate, and heavy-duty capacity allow efficient machining of large components with brilliant accuracy and reliability.Q: Where can the DMU 210P be installed and operated efficiently?

A: The DMU 210P is ideal for installation in industrial facilities, manufacturing hubs, and workshops that require precision production of complex or large-scale parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

DMU ULTRASONIO10

Minimum Order Quantity : 1 Unit

Power : 2200 W

Color : Blue / Grey

Capacity : 100 liters

Used For : Industrial Component Cleaning

Voltage : 220 V

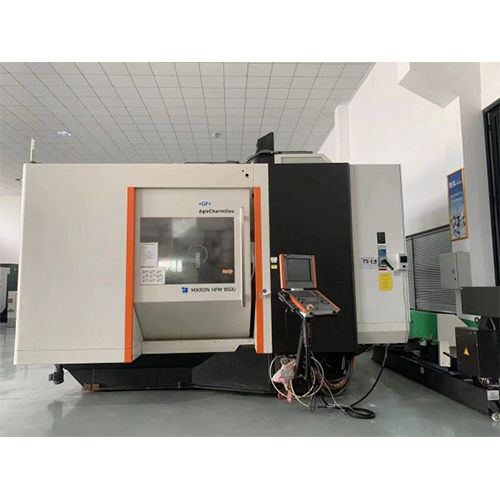

Mikron HPM1850u

Minimum Order Quantity : 1 Unit

Power : 30 kW spindle motor

Color : White / Grey

Capacity : Workpiece up to 1,850 mm diameter

Used For : Highperformance milling and precision machining of complex parts

Voltage : 400V / 50Hz

MAZAK VORTEX i-630V-6 Horizontal Five-Axis Machining Center

Minimum Order Quantity : 1 Unit

Power : Spindle motor 50 HP (37 kW)

Color : Industrial Grey/White

Capacity : Workpiece size up to 1,000 mm x 850 mm

Used For : Highprecision complex part machining; Aerospace, automotive, and industrial components

Voltage : 400V / 50Hz

DMU70eVo linear

Minimum Order Quantity : 1 Unit

Power : 32 kVA

Color : White/Grey

Capacity : 700 mm (X) x 600 mm (Y) x 520 mm (Z)

Used For : Precision Machining and Milling of Metals and Alloys

Voltage : 400 V

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry