DMU 50 Five Axis Machining Center

DMU 50 Five Axis Machining Center Specification

- Dimension (L*W*H)

- 2630 x 2500 x 2250 mm

- Machine Type

- Five Axis Machining Center

- Voltage

- 400 V

- Feature

- Simultaneous 5-Axis Machining, High-Precision

- Used For

- Precision CNC Machining, Milling of Complex Parts

- Condition

- Used

- Color

- White / Grey

- Capacity

- Max Workpiece Diameter 650 mm

- Manufacturing Year

- 2020

- Weight

- 5100 kg

- Power

- 18 kW

- Output

- High-speed Machining Output

- Positioning Accuracy

- +/- 0.006 mm

- Lighting

- LED Internal Lighting

- Travel (X/Y/Z)

- 650 / 520 / 475 mm

- Rapid Traverse Rate

- 42 m/min

- Table Size

- 650 mm diameter

- Machine Enclosure

- Full Sheet Metal Enclosure with Safety Glass

- Interface

- Ethernet, USB

- Control System

- Siemens 840D

- Type of Tool Holder

- HSK-A63

- Spindle Speed

- Up to 15,000 RPM

- Cooling System

- Integrated Chip Conveyor & Coolant System

- Max Table Load

- 300 kg

- Tool Magazine Capacity

- 30 Tools

- Lubrication

- Automatic Centralized Lubrication

- Air Supply Required

- 6 bar

DMU 50 Five Axis Machining Center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About DMU 50 Five Axis Machining Center

Features, Applications & Usage: Unmatched Versatility and Precision

The DMU 50 Five Axis Machining Center boasts impeccable simultaneous 5-axis machining, high spindle speeds, and a substantial 650mm worktable for diverse parts. Its elite precision is ideal for aerospace, automotive, and mold making. Used for milling complex geometries, this machine accommodates rapid tool changes and intricate part processing. The robust enclosure, integrated cooling, and advanced control system ensure safety and efficiency, making it an essential choice for high-value CNC production applications.

Export Markets, Sample Policy & Payment Terms: Seamless Global Operations

The DMU 50 is primarily exported to global markets with shipped goods supported by robust handling procedures. Market value is maintained through competitive quotations tailored to client requirements. Flexible payment terms and sample policies cater to varied customer needs, ensuring customer confidence with every transaction. Each shipment is fully documented, ensuring transparent communication and swift fulfillment for distributors, exporters, manufacturers, suppliers, and traders worldwide.

FAQ's of DMU 50 Five Axis Machining Center:

Q: How does the DMU 50 Five Axis Machining Center enhance precision in CNC operations?

A: The DMU 50 delivers elite precision with simultaneous 5-axis machining, Siemens 840D control, and exceptional positional accuracy (+/- 0.006 mm), ensuring every part meets exacting standards.Q: What industries and applications benefit most from using this machining center?

A: This machine is invaluable in aerospace, automotive, energy, and mold making industries due to its capability to mill complex parts and execute intricate geometries efficiently.Q: Where can the DMU 50 be shipped, and what markets does it serve?

A: The DMU 50 serves global markets-including Asia, Europe, and the Americas-through trusted distributors, manufacturers, and exporters with international shipping options available.Q: What is the process for obtaining a quotation and arranging payment for the DMU 50?

A: Request a detailed quotation by contacting the distributor, supplier, or manufacturer directly. Payment terms are flexible and can be negotiated to align with the buyer's requirements for smooth, transparent transactions.Q: What are the key benefits of the DMU 50's integrated cooling and lubrication systems?

A: The machine's integrated chip conveyor and automatic centralized lubrication system guarantee optimal performance, extended tool life, and reduced downtime, enhancing overall productivity and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

DMU 60 monoblock

Minimum Order Quantity : 1 Unit

Condition : Used

Used For : Precision metal cutting, milling of complex components

Weight : ~8000 kg

Manufacturing Year : 2011

Capacity : 600 mm maximum workpiece diameter

VARIAXIS i-700 Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Condition : New

Used For : Precision 5axis machining of complex components

Weight : Approx. 11,000 kg

Manufacturing Year : 2023

Capacity : Workpiece size max. 850 x 500 mm, Table load max. 500 kg

MAZAK VORTEX i-630V-6 Horizontal Five-Axis Machining Center

Minimum Order Quantity : 1 Unit

Condition : New

Used For : Highprecision complex part machining; Aerospace, automotive, and industrial components

Weight : Approx. 21,000 kg

Manufacturing Year : Recent (Exact year not specified)

Capacity : Workpiece size up to 1,000 mm x 850 mm

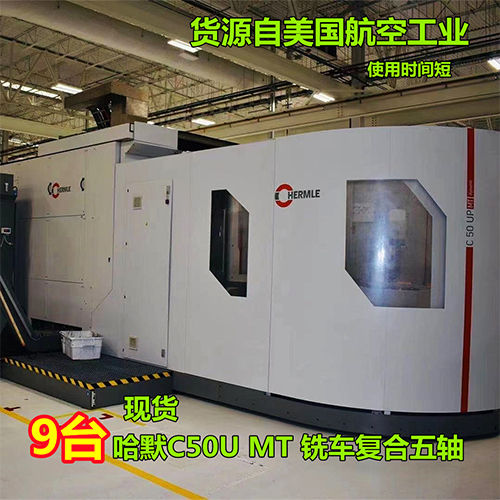

German Hermle C50U MT

Minimum Order Quantity : 1 Unit

Condition : Used, Excellent

Used For : Precision Machining, Milling and Turning, MultiAxis Component Manufacturing

Weight : Approx. 28,000 kg

Manufacturing Year : 2010

Capacity : Workpiece: Max. 1000 mm x 810 mm, Max. 2000 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry