DMU 160PduoBlock Five Axis Machining Center

DMU 160PduoBlock Five Axis Machining Center Specification

- Manufacturing Year

- nan

- Capacity

- Machining range X/Y/Z: 1600/1600/1100 mm

- Used For

- Precision machining of complex components

- Output

- High-speed, multi-axis machining operations

- Weight

- Approximately 27,000 kg

- Color

- White/Grey

- Dimension (L*W*H)

- 5175 x 4200 x 3226 mm

- Voltage

- 400 V

- Machine Type

- Five Axis Machining Center

- Condition

- Used

- Power

- 63 kVA (typical connection value)

- Feature

- DuoBlock design for enhanced rigidity and accuracy

- Rotary Axis (C/B)

- +/- 120 degrees (B), 360 degrees continuous (C)

- Tool Magazine Capacity

- 60 tools (standard), expandable

- Axis Travel (X/Y/Z)

- 1600 mm / 1600 mm / 1100 mm

- Spindle Speed

- Up to 12,000 rpm (standard), 18,000 rpm (optional)

- Table Load Capacity

- Up to 3,000 kg

- Rapid Traverse Rate

- 40 m/min (X, Y, Z axes)

- Control System

- SIEMENS 840D Solutionline

- Coolant System

- High-pressure internal coolant system

- Chip Conveyor

- Standard

- Lubrication

- Centralized automatic lubrication system

- Accuracy

- 0.008 mm

- Automation

- Automation-ready with pallet changer and robotic integration

DMU 160PduoBlock Five Axis Machining Center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About DMU 160PduoBlock Five Axis Machining Center

Versatile Application & Media Usage for DMU 160PduoBlock

The DMU 160PduoBlock Five Axis Machining Center is engineered for precision production of complex parts using various metals and alloys as its primary application media. Its application method involves advanced milling and simultaneous five-axis machining, ideal for aerospace, automotive, and mold manufacturing industries. With a user-friendly SIEMENS control system and automation-ready setup, the machine ensures seamless operation and minimal manual intervention, providing reliable and exceptional results across broad industrial applications.

Certifications, Sample Policy & Delivery Terms: DMU 160PduoBlock

Order completion for the DMU 160PduoBlock is prompt, with estimated delivery from FOB ports in China. The machine is offered with traceable certifications to ensure quality compliance for international buyers. Customers may request detailed documentation or sample testing policies as part of their estimate and offer process. As a reliable distributor, exporter, and supplier, we strive to meet stringent market standards and facilitate smooth global transactions for every order.

FAQs of DMU 160PduoBlock Five Axis Machining Center:

Q: How does the DMU 160PduoBlock enhance precision machining operations?

A: The DMU 160PduoBlock utilizes advanced duoBlock design and five-axis technology to achieve superior rigidity, accuracy (0.008 mm), and repeatability for complex component manufacturing.Q: What applications and industries benefit most from this machining center?

A: This machine is ideal for aerospace, automotive, die and mold manufacturing, and other sectors demanding multi-axis precision, high-speed operations, and reliable automation.Q: When is it advisable to upgrade to the optional 18,000 rpm spindle?

A: Upgrading to the 18,000 rpm spindle is recommended when high-speed machining, improved surface finishes, or processing of heat-sensitive materials are required for production efficiency.Q: Where can I find certifications and shipping arrangements?

A: Certifications and shipping arrangements are provided upon order completion, with FOB ports located in China and all required documentation available for international buyers.Q: What is the process for integrating automation with this machining center?

A: The DMU 160PduoBlock is automation-ready, allowing straightforward integration of pallet changers and robotic systems to enhance production throughput and reduce manual labor.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

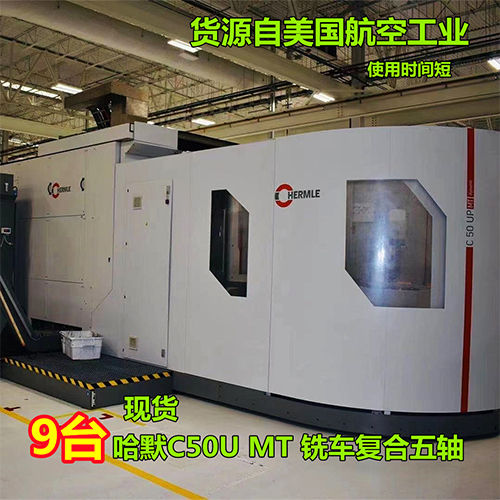

German Hermle C50U MT

Minimum Order Quantity : 1 Unit

Machine Type : 5Axis CNC Machining Center with Turning (MillTurn)

Capacity : Workpiece: Max. 1000 mm x 810 mm, Max. 2000 kg

Condition : Used, Excellent

Voltage : 400 V, 50 Hz

Dimension (L*W*H) : Approx. 7300 mm x 5550 mm x 3620 mm

DMU70eVo linear

Minimum Order Quantity : 1 Unit

Machine Type : Universal CNC Milling Machine

Capacity : 700 mm (X) x 600 mm (Y) x 520 mm (Z)

Condition : Used

Voltage : 400 V

Dimension (L*W*H) : 3,000 x 2,800 x 2,900 mm

DMU ULTRASONIO10

Minimum Order Quantity : 1 Unit

Machine Type : Ultrasound Cleaning Machine

Capacity : 100 liters

Condition : New

Voltage : 220 V

Dimension (L*W*H) : 800 mm x 600 mm x 900 mm

OPS HAWK750

Minimum Order Quantity : 1 Unit

Machine Type : Hydraulic Press Brake Machine

Capacity : 750 Ton

Condition : New

Voltage : 415 V

Dimension (L*W*H) : 2900 x 1900 x 2400 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry