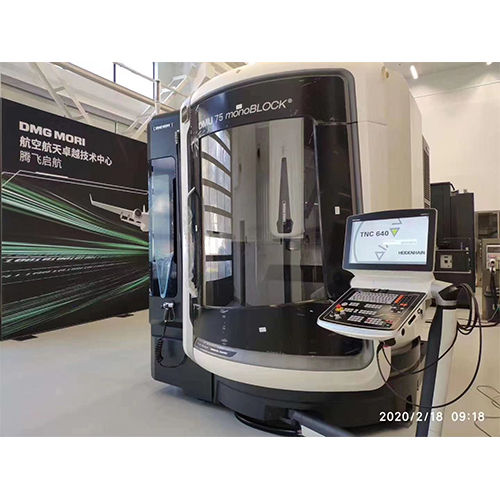

DMU 75 monoBLOCK Five Axis Machining Center

DMU 75 monoBLOCK Five Axis Machining Center Specification

- Output

- High precision multi-axis machining operations

- Capacity

- Pallet size 750 mm x 600 mm

- Dimension (L*W*H)

- Approx. 3100 mm x 2500 mm x 2900 mm

- Condition

- Used

- Weight

- Approx. 12,000 kg

- Voltage

- 400 V / 50 Hz

- Color

- Standard (White + Grey)

- Machine Type

- Five Axis Machining Center

- Used For

- Precision complex part machining, aerospace, automotive, mold & die industries

- Power

- Main spindle motor: 35 kW

- Feature

- Simultaneous 5-axis machining, high rigidity, heavy-duty cutting capability, integrated swivel rotary table

- Accuracy

- Positioning: ±3 µm / Repetition: ±2 µm

- Chip Conveyor

- Standard

- Control System

- Heidenhain iTNC 530 or Siemens 840D (varies by model)

- Enclosure

- Fully enclosed working area for safety and chip management

- Spindle Speed

- Up to 18,000 rpm

- Foundation Requirement

- Reinforced concrete base recommended

- Lubrication System

- Centralized automatic lubrication

- Swivel Rotary Table

- Integrated, 600 mm diameter, 360° (C-axis)

- Coolant System

- High-pressure internal/external through-spindle coolant

- Travel (X/Y/Z)

- 750 mm / 650 mm / 560 mm

- Rapid Traverse Rate

- Up to 40 m/min (X/Y/Z)

- Maximum Workpiece Weight

- Up to 600 kg

- Tool Magazine

- 30/60/120 tools (option-dependent)

DMU 75 monoBLOCK Five Axis Machining Center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About DMU 75 monoBLOCK Five Axis Machining Center

DMU 75 monoBLOCK Five Axis Machining Center: Applications and Advantages

The DMU 75 monoBLOCK Five Axis Machining Center is preferred for its exceptional precision and heavy-duty cutting power. Used as a primary tool in aerospace, automotive, and mold & die industries, this machine redeems complex machining tasks with simultaneous multi-axis operations. Its robust foundation and advanced coolant system ensure sustained performance, while high spindle speeds and rigid construction contribute to productivity and top-tier results, establishing it as an essential for high-value manufacturing environments.

Global Supply and Export Information

The DMU 75 monoBLOCK Five Axis Machining Center is shipped worldwide, with main export markets in Asia, Europe, and North America. Supply ability meets the demands of distributors, exporters, and manufacturers seeking rarefied precision. FOB port options include major Chinese seaports, ensuring smooth handover post-quotation. Each machine is carefully packed and delivered to redeem value for clients in advanced manufacturing sectors, with flexible supply chain solutions tailored to global needs.

FAQ's of DMU 75 monoBLOCK Five Axis Machining Center:

Q: How does the DMU 75 monoBLOCK ensure precision in multi-axis machining operations?

A: The DMU 75 monoBLOCK maintains top-tier precision through its potent control system options (Heidenhain or Siemens), robust construction, and accurate positioning and repetition (3 m and 2 m, respectively), delivering consistent results even in demanding simultaneous 5-axis applications.Q: What industries commonly use the DMU 75 monoBLOCK Five Axis Machining Center?

A: This machine is widely used in aerospace, automotive, and mold & die industries, where rarefied precision, potent cutting capabilities, and complex part production are required for high-value components.Q: Where is the DMU 75 monoBLOCK typically exported from, and what is the supply capacity?

A: The DMU 75 monoBLOCK is exported from China, utilizing major FOB ports, with supply ability tailored to manufacturers, traders, and distributors across multiple continents, including Asia, Europe, and North America.Q: What is the process for receiving a quotation and handover for this machining center?

A: To redeem a DMU 75 monoBLOCK, clients can request a quotation from authorized distributors. Upon agreement, the handover process includes shipment arrangements, thorough pre-export inspection, and delivery to the designated FOB port.Q: What are the benefits of the DMU 75 monoBLOCK's integrated swivel rotary table?

A: The integrated swivel rotary table allows 360 manipulation of workpieces up to 600 kg, enhancing flexibility for complex geometries and boosting efficiency in simultaneous multi-axis machining operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

DMU70eVo linear

Minimum Order Quantity : 1 Unit

Feature : Linear Drives, 5Axis Simultaneous Machining, High Spindle Speed, Rigid Construction

Color : White/Grey

Voltage : 400 V

Weight : Approx. 8,500 kg

Power : 32 kVA

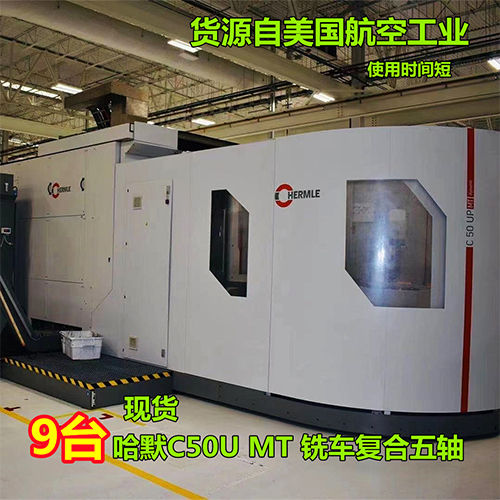

German Hermle C50U MT

Minimum Order Quantity : 1 Unit

Feature : Simultaneous 5Axis Machining, Integrated Turning Function, High Rigidity, Precision Performance, Tool Magazine

Color : Grey and Blue

Voltage : 400 V, 50 Hz

Weight : Approx. 28,000 kg

Power : Main Spindle: 63 kW, 18,000 rpm

Fidia K199 Five Axis Linkage High Speed Vertical Machining Center

Minimum Order Quantity : 1 Unit

Feature : High Speed, High Precision, Five Axis Simultaneous Operation

Color : White and Blue

Voltage : 400 V

Weight : 21000 kg

Power : 45 kW

Mazak VORTEX i-630V-6 horizontal five axis machining center (sold on behalf of customers)

Minimum Order Quantity : 1 Unit

Feature : Simultaneous 5Axis Machining, HighSpeed Spindle, Automatic Tool Changer

Color : White / Grey

Voltage : 220/400V, 3 Phase

Weight : Approx. 21,000 kg

Power : Spindle Motor 37 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry