DMU 100P monoblock

DMU 100P monoblock Specification

- Voltage

- 400 V

- Machine Type

- DMU 100P Monoblock Universal Machining Centre

- Color

- White-Grey

- Used For

- Precision CNC Milling and Machining

- Dimension (L*W*H)

- 4,500 mm x 3,200 mm x 3,200 mm

- Manufacturing Year

- 2005

- Feature

- 5-Axis Simultaneous Machining, High Rigidity, Integrated Table

- Output

- High Precision Metal Parts

- Capacity

- Machine Travel: X=1,000 mm, Y=710 mm, Z=710 mm

- Weight

- Approximately 18,000 kg

- Condition

- Used

- Power

- 45 kVA

- Control System

- Heidenhain iTNC530

- Main Drive

- 20 kW

- Tool Magazine

- 32 Slots (Automatic Tool Changer)

- Cooling System

- Internal Coolant Supply

- Table Size

- 1,070 mm x 710 mm

- Chip Conveyor

- Yes, Included

- Spindle Speed

- Up to 18,000 rpm

- Repeating Accuracy

- ± 0.005 mm

- Max Workpiece Weight

- 2,000 kg

DMU 100P monoblock Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About DMU 100P monoblock

Why Choose the DMU 100P Monoblock?

The DMU 100P Monoblock delivers competitive advantages through its high rigidity, enviable accuracy, and 5-axis simultaneous machining, making it ideal for precision applications in automotive, aerospace, and component manufacturing. Its polished surface capabilities adapt seamlessly to various metals, presenting a grandiose solution for intricate surface finishes. Commercial users benefit from consistent high-precision output, boosting both productivity and reputation in demanding environments.

Packaging and Delivery for the DMU 100P Monoblock

All goods are shipped securely with full transport protection to ensure safe arrival. The DMU 100P Monoblock is packaged to withstand international freight, with supply ability supporting bulk or individual delivery as per client requirements. We ensure that every unit departs efficiently from the designated FOB port in China, facilitating your import process with reliable tracking and on-time delivery of sophisticated equipment.

FAQ's of DMU 100P monoblock:

Q: How does the DMU 100P Monoblock support high-precision machining?

A: The DMU 100P Monoblock features an integrated Heidenhain iTNC530 control system, 0.005 mm repeating accuracy, and robust 5-axis simultaneous machining, enabling consistent, high-precision results in complex part production.Q: What industries benefit most from using this machining centre?

A: Industries such as aerospace, automotive, mold making, and high-precision component manufacturing gain substantial benefits from the DMU 100P Monoblock due to its advanced performance and flexibility with diverse materials.Q: Where can the DMU 100P Monoblock be delivered internationally?

A: We arrange global shipments from the FOB port in China, offering worldwide delivery options for distributors, exporters, manufacturers, suppliers, and traders.Q: What is included in the machine's standard configuration?

A: Standard features include a 1,070 x 710 mm table, 32-slot tool magazine with automatic changer, a main drive of 20 kW, internal coolant supply, chip conveyor, and a Heidenhain iTNC530 control, all enclosed in a white-grey finish.Q: How is the packaging handled for safe transport?

A: The DMU 100P Monoblock is securely packed with protective materials designed to safeguard the machine during transport, ensuring it remains in excellent condition from shipping to delivery.Q: What is the supply ability and lead time for orders?

A: We support bulk and individual deliveries, with lead times and supply schedules customized to fit each client's requirements, ensuring prompt and reliable service every time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

DMU ULTRASONIC 10 Ultrasonic High Frequency Five Axis Linkage Machining Center

Minimum Order Quantity : 1 Unit

Voltage : 400 V, 50/60 Hz

Weight : Approx. 4500 kg

Capacity : Workpiece 600 mm x 500 mm, max. 50 kg

Output : High precision finished machined components

Machine Type : Ultrasonic High Frequency Five Axis Linkage Machining Center

DMC 160FD Hi-Dyn Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Voltage : 400 V, 50 Hz

Weight : Approx. 28,000 kg

Capacity : Workpiece up to 1,600 mm table diameter

Output : High speed and accuracy for aerospace, automotive, mold & die

Machine Type : Five Axis Machining Center

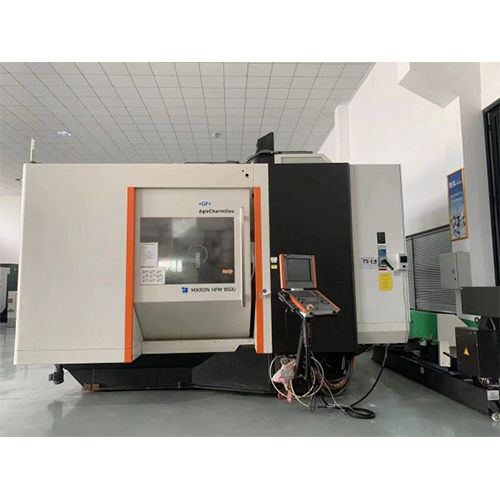

Mikron HPM1850u

Minimum Order Quantity : 1 Unit

Voltage : 400V / 50Hz

Weight : 17,000 kg

Capacity : Workpiece up to 1,850 mm diameter

Output : Highspeed spindle, multiaxis positions

Machine Type : Vertical Machining Center (5Axis)

Germany DMU200P

Minimum Order Quantity : 1 Unit

Voltage : 400 V

Weight : Approximately 18,000 kg

Capacity : Table load up to 2,250 kg

Output : High precision finished parts

Machine Type : CNC Universal Milling Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry