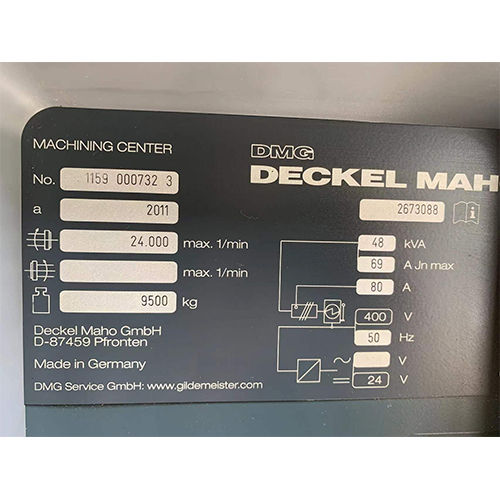

Germany DMC85mono Five-axis Linkage Machining Center

Germany DMC85mono Five-axis Linkage Machining Center Specification

- Condition

- Used

- Machine Type

- Five-axis Linkage Machining Center

- Power

- 27 kW

- Color

- White/Grey

- Weight

- 11500 kg

- Capacity

- Up to 1200 kg table load

- Voltage

- 400V

- Dimension (L*W*H)

- 3200 mm x 3200 mm x 2700 mm

- Manufacturing Year

- 2021

- Used For

- Precision machining of complex metal parts

- Output

- Fully finished five-axis components

- Feature

- High rigidity, high precision, and long service life

- Y-axis Travel

- 700 mm

- Table Diameter

- 700 mm

- Z-axis Travel

- 600 mm

- Spindle Speed

- Up to 18,000 rpm

- Control System

- Heidenhain iTNC 640

- Max Workpiece Height

- 600 mm

- Positioning Accuracy

- 0.005 mm

- Coolant System

- Internal and external coolant supply

- Repeatability

- 0.003 mm

- Max Workpiece Diameter

- 800 mm

- Minimum Increment

- 0.001 mm

- ATC Type

- Chain type automatic tool changer

- X-axis Travel

- 850 mm

- Tool Magazine Capacity

- 60 tools

- Ambient Temperature Range

- 10°C to 40°C

Germany DMC85mono Five-axis Linkage Machining Center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Germany DMC85mono Five-axis Linkage Machining Center

Areas of Application and Special Features

The Germany DMC85mono Five-axis Linkage Machining Center excels in the precision machining of complex metal parts. Its high rigidity, extraordinary accuracy, and flexible five-axis capabilities make it a top choice for industries such as aerospace, automotive, and medical equipment. Noteworthy features include a vast tool magazine, advanced coolant system, and ability to handle large workpieces. Other applications span mold-making and high-precision component manufacturing, thanks to its impressive repeatability and robust construction.

Certifications, Sale Price, and Transportation Options

The Germany DMC85mono Five-axis Linkage Machining Center comes with all necessary certifications for international distribution. Take advantage of our sale price, which includes options for express shipping from the designated FOB port. We ensure secure transportation to your facility, maintaining machine integrity. A sample policy is available on request to inspect the product before purchase. This guarantees that our customers receive reliable, certified machinery tailored to their operational needs.

FAQ's of Germany DMC85mono Five-axis Linkage Machining Center:

Q: How does the Germany DMC85mono Machining Center ensure precision during operation?

A: The machining center delivers superior precision through its Heidenhain iTNC 640 control system, high positioning accuracy of 0.005 mm, and exceptional repeatability of 0.003 mm. These features guarantee consistent and accurate machining results for complex parts.Q: What industries benefit most from using this five-axis machining center?

A: Industries such as aerospace, automotive, medical device manufacturing, and advanced mold production benefit greatly from the machine's rigidity, precision, and robust capabilities to handle intricate metal parts.Q: Where is the machine shipped from and can customers request express shipping?

A: The Germany DMC85mono is shipped from our designated FOB port in China. Express shipping options are available to ensure quick and safe arrival at your facility.Q: What is the process for ordering and receiving a sample of this machining center?

A: Customers can request a sample policy to inspect the product. Upon agreement, we arrange shipment and provide detailed product documentation, ensuring full transparency before finalizing the sale.Q: When is the best time to order this machining center for optimal delivery?

A: Ordering as soon as possible is advantageous, especially if you require timely integration into your production process. We recommend picking yours today to benefit from current stock availability and expedited shipping.Q: What are the standout features that set this machine apart from competitors?

A: Noteworthy features include a five-axis linkage, advanced internal and external coolant system, high-capacity tool magazine, remarkable positioning accuracy, and the ability to accommodate large and heavy workpieces-making it stand out in both performance and versatility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

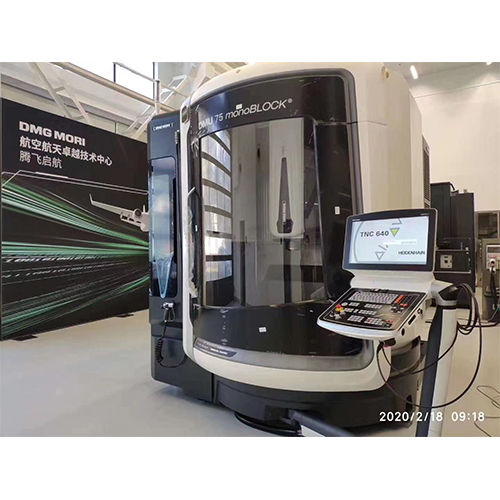

Demaji DMU75 mono block five axis machining center

Minimum Order Quantity : 1 Unit

Capacity : 750 mm worktable, 600 kg max table load

Voltage : 400 V

Condition : New

Machine Type : Five Axis Machining Center

Color : White/Grey

Hermle C50U Five Axis Maching Center

Minimum Order Quantity : 1 Unit

Capacity : Workpiece weight up to 2,000 kg

Voltage : 400 V

Condition : Used

Machine Type : Five Axis Machining Center

Color : White/Grey

Mazak VORTEX i-630V-6 horizontal five axis machining center (sold on behalf of customers)

Minimum Order Quantity : 1 Unit

Capacity : Pallet Size 630 mm, Max Workpiece Dia. 1,050 mm, Max Workpiece Height 900 mm

Voltage : 220/400V, 3 Phase

Condition : Used (Excellent Condition)

Machine Type : Horizontal Five Axis Machining Center

Color : White / Grey

DMU80 MONOBLOCK Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Capacity : Up to 600 kg on rotary table

Voltage : 400 V

Condition : Used

Machine Type : Five Axis Machining Center

Color : White / Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry