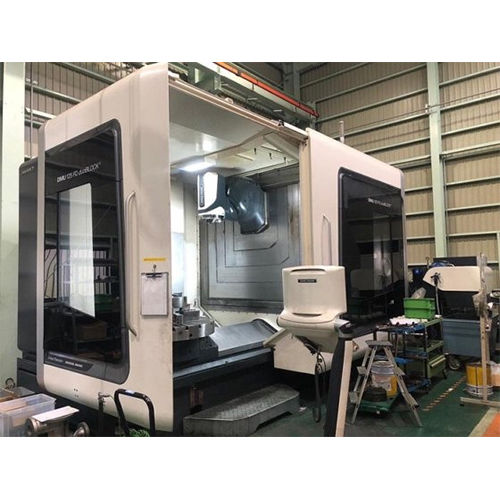

DMU 125FD duoBLOCK Five Axis Machining Center

DMU 125FD duoBLOCK Five Axis Machining Center Specification

- Power

- Main spindle drive 35 kW

- Feature

- duoBLOCK design for rigidity, integrated rotary table, large working area

- Capacity

- Workpiece up to 1500 kg

- Color

- White/Grey

- Dimension (L*W*H)

- Approx. 4300 x 3600 x 2950 mm

- Used For

- High-precision milling, contouring, and five-axis simultaneous machining

- Voltage

- 400 V

- Output

- High-speed & high-accuracy machining results

- Machine Type

- Five Axis Machining Center

- Y-axis Travel

- 1000 mm

- Safety Features

- Full enclosure, interlocked doors, emergency stop

- Tool Magazine Capacity

- 60 tools (optional up to 120)

- X-axis Travel

- 1250 mm

- Max Table Load

- 2000 kg

- Rapid Traverse Rate

- up to 60 m/min

- Table Size

- Ø 1000 mm

- Z-axis Travel

- 1000 mm

- Chip Conveyor

- Integrated automatic chip disposal

- CNC Controller

- Siemens Sinumerik 840D

- Accuracy

- Positioning accuracy 0.008 mm

- Spindle Speed

- 20,000 rpm

- Environmental Compliance

- CE Certified

- Coolant System

- High-pressure through spindle

DMU 125FD duoBLOCK Five Axis Machining Center Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About DMU 125FD duoBLOCK Five Axis Machining Center

Special Features and Plant Application

The DMU 125FD duoBLOCK Five Axis Machining Center boasts its distinguished duoBLOCK design for unrivaled rigidity and precision. Astounding features like a large integrated rotary table, high-capacity tool magazine, and high-pressure coolant enable flawless operations in aerospace, automotive, and heavy machinery plants. Its versatile five-axis contouring delivers top-quality milling and simultaneous machining for intricate commercial uses. Designed for large working areas, it assures reliability in demanding production environments.

FOB Port, Certifications, and Domestic Market Rates

The DMU 125FD is ready for international exchange via major China FOB ports, supported by efficient transport services. CE-certified quality and safety ensure compliance with global standards. Main domestic market rates benefit from prompt availability and strategic distribution channels, facilitating swift procurement and delivery. Exporters, suppliers, manufacturers, and traders can take advantage of validated certifications, reliable transport logistics, and competitive pricing for scalable plant integration.

FAQ's of DMU 125FD duoBLOCK Five Axis Machining Center:

Q: How does the duoBLOCK design benefit high-precision machining on the DMU 125FD?

A: The duoBLOCK design provides exceptional rigidity and vibration dampening, leading to improved positioning accuracy (0.008 mm) and flawless five-axis simultaneous machining results, which are essential for high-precision milling applications.Q: What commercial industries commonly use the DMU 125FD Machining Center?

A: This five-axis machining center is widely used in aerospace, automotive, heavy machinery, and any industry requiring distinguished contouring and high-speed milling of complex parts.Q: When should you consider upgrading the tool magazine capacity on the DMU 125FD?

A: Upgrade the tool magazine to 120 tools when your process demands frequent tool changes or when manufacturing complex components, enhancing operational flexibility and productivity.Q: Where can the DMU 125FD be exported and what transport services are available?

A: The DMU 125FD can be exported globally from China via major FOB ports, with robust transport services ensuring safe and reliable international delivery.Q: What safety and environmental compliance features does the DMU 125FD offer?

A: Certified for CE compliance, the DMU 125FD includes full enclosure, interlocked doors, emergency stop protection, and integrated chip disposal for safe, environmentally responsible plant operation.Q: How does the high-pressure spindle coolant system improve machining efficiency?

A: The high-pressure through-spindle coolant system enhances chip removal, prolongs tool life, and enables high-speed cutting while maintaining top-quality surface finishes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Axis Machining Center Category

German Hermle C50U

Minimum Order Quantity : 1 Unit

Capacity : Large Component Machining

Feature : High Precision, Fully Automated, MultiAxis Control

Condition : Used

Manufacturing Year : 2012

Used For : Precision Milling and Machining

Germany Hammer C42U Five Axis Machining Center

Minimum Order Quantity : 1 Unit

Capacity : Max. workpiece size 850 mm x 1000 mm x 700 mm

Feature : Simultaneous 5axis machining, high rigidity structure, advanced control system

Condition : New

Manufacturing Year : 2022

Used For : High precision milling, drilling, and machining of metal components

DMU 100 mono block

Minimum Order Quantity : 1 Unit

Capacity : Workpiece Height Max 1,200 mm, Max Table Load 2,000 kg

Feature : MonoBLOCK Construction, High Rigidity, 5Axis Simultaneous Machining, Compact Footprint, High Accuracy

Condition : Used, Excellent

Manufacturing Year : 2015

Used For : CNC Milling, Highprecision Machining, Tool and Mould Making, Aerospace Components

Germany DMU125P

Minimum Order Quantity : 1 Unit

Capacity : Workpiece max. 2000 kg

Feature : 5axis CNC, precision drive, rigid construction, automatic tool changer

Condition : Used

Manufacturing Year : 2005

Used For : Highprecision metal part milling

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry