Price 1999 USD ($)/ Unit

MOQ : 1 Unit

Specification

- पावर

- 7.5 kW

- वोल्टेज

- 380V

- आयाम (एल* डब्ल्यू* एच)

- 3100 x 1500 x 1800 mm

- शर्त

- Used

- वज़न

- Approx. 3.2 Tons

- क्षमता

- 300~400 pcs/min

- के लिए इस्तेमाल किया गया

- Bolt Manufacturing

- रंग

- Blue

- फ़ीचर

- 2 Mold 2 Blow Design

- आउटपुट

- Bolt

- मशीन का प्रकार

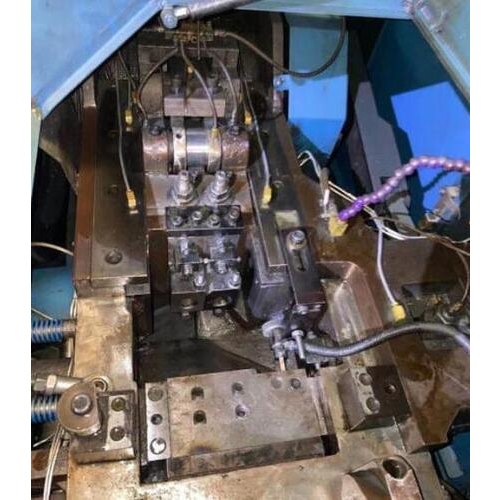

- 2 Mold 2 Blow Bolt Making Machine

Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- ,

- मुख्य निर्यात बाजार

- , , , , , , , ,

- मुख्य घरेलू बाज़ार

About

Brand: South KoreaCommodity unit:unit

Inventory quantity: 1

Code: 14228

(The price of the website platform is not the actual quotation, please contact us for the specific quotation according to your products and suitable machine models)

Efficient Double Mold Double Blow Design

With its innovative 2 mold 2 blow configuration, the CH0322 delivers high efficiency and consistent quality in bolt manufacturing. This ensures rapid production cycles, making it an ideal choice for industries requiring a steady and reliable supply of bolts. Operators benefit from fully-automatic feeding and centralized lubrication, minimizing downtime and maintenance efforts while optimizing performance and longevity.

Robust Build and User-Friendly Operation

Manufactured in Korea South, the CH0322 upholds high durability standards. The machine features a semi-automatic control system along with manual overrides, offering flexibility to accommodate various production needs. Coupled with low noise levels below 80 dB and a compact footprint, it is suitable for both large factories and smaller facilities aiming for efficient, quiet manufacturing environments.

FAQ's of Used Korea CH0322 2 Mold 2 Blow Bolt Making Machine:

Q: How does the CH0322 2 Mold 2 Blow Bolt Making Machine operate?

A: The machine utilizes a double mold and double blow system to shape and form bolts from steel rods or wires. Bolts in the M3-M8 range are processed at speeds up to 400 pieces per minute, facilitated by the automatic vibratory feeder and supported by a centralized lubrication system.Q: What are the main benefits of using this used bolt making machine?

A: Key benefits include high-speed bolt production, consistent output quality due to the 2 mold 2 blow design, and reduced maintenance through automated lubrication. Its semi-automatic controls enhance user flexibility, while low noise levels create a safer, more comfortable workplace.Q: Where can the CH0322 2 Mold 2 Blow machine be used?

A: This machine is suitable for factories, workshops, and production plants involved in bolt manufacturing. Its compact size allows it to fit into various industrial settings, from large distribution facilities to specialized manufacturing units.Q: What is the installation and power requirement for this equipment?

A: The CH0322 requires 380V electrical supply for its 7.5 kW AC electric motor and an air supply pressure of 0.8 MPa. Due to its dimensions and weight (approx. 3.2 tons), professional installation in a stable, ventilated workspace is recommended.Q: How is steel rod feeding managed in the CH0322?

A: An automatic vibratory feeder is integrated into the system, which streamlines the feeding of steel rods or wire, ensuring continuous and uniform material supply for efficient bolt production.Q: What size and types of bolts can this machine produce?

A: This bolt making machine processes steel rods or wires to manufacture bolts within the M3 to M8 size range, adapting to various manufacturing requirements in terms of diameter and length.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in इस्तेमाल किया मल्टी स्टेशन बोल्ट मेकिंग मशीन Category

Dongguan Wangketong मशीनरी उपकरण कं, Ltd

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें