Price 1985 USD ($)/ Unit

MOQ : 1 Unit

Specification

- पावर

- 11 kW

- वज़न

- Approximately 4200 kg

- आयाम (एल* डब्ल्यू* एच)

- 3200 mm x 1400 mm x 1800 mm

- फ़ीचर

- High efficiency, Precision forming, Robust build, Easy operation

- मशीन का प्रकार

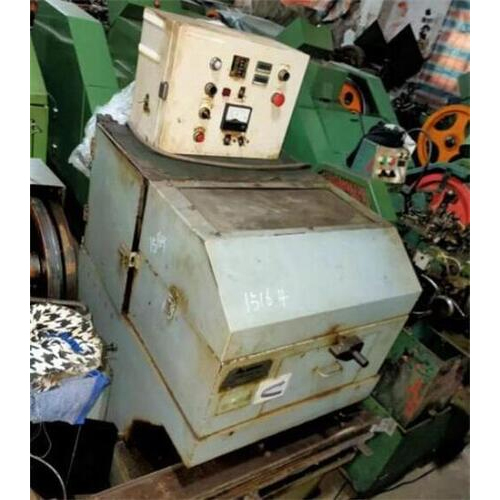

- 2 Mold 2 Blow Bolt Making Machine

- के लिए इस्तेमाल किया गया

- Bolt manufacturing

- शर्त

- Used

- क्षमता

- Approximately 40-90 pieces per minute

- वोल्टेज

- 380V, 3 Phase

- आउटपुट

- Finished hex bolts and fasteners

- रंग

- Standard Industrial Grey

Trade Information

- Minimum Order Quantity

- 1 Unit

- भुगतान की शर्तें

- ,

- मुख्य निर्यात बाजार

- , , , , , , , ,

- मुख्य घरेलू बाज़ार

About

Brand: Ayase JapanCommodity unit:unit

Inventory quantity: 1

Code: 15164

(The price of the website platform is not the actual quotation, please contact us for the specific quotation according to your products and suitable machine models)

High-Precision Bolt Manufacturing

Engineered for precision, the Ayase 2 Mold 2 Blow Bolt Making Machine consistently delivers accurately formed hex bolts and fasteners. Its robust build guarantees durability, while the advanced Japanese control system ensures reliable operation. With two molds and two blow stations, it can produce a broad range of bolt sizes, meeting diverse industrial requirements.

Streamlined Semi-Automatic Production

Designed with productivity in mind, this machine features an automatic bar feeder and a centralized lubrication system, reducing manual intervention and ensuring smoother, continuous operation. Its semi-automatic nature provides flexibility while enabling operators to maintain oversight and easily adjust production cycles as needed.

Ideal for Steel and Alloy Applications

Whether working with steel, stainless steel, or alloy steel, the Ayase machine accommodates a range of material applications. Its adjustable settings make it suitable for bolt manufacturing businesses requiring versatility and consistency in product output, handling diameters from M5 to M12 and lengths up to 100 mm.

FAQ's of Used Japan Ayase 2 Mold 2 Blow Bolt Making Machine:

Q: How does the automatic feeding system function in the Ayase 2 Mold 2 Blow Bolt Making Machine?

A: The machine is equipped with an automatic bar feeder that supplies raw material bars to the forming section without manual intervention. This enhances workflow efficiency and ensures a constant, uninterrupted supply during bolt production.Q: What types of materials can be processed using this bolt making machine?

A: This bolt making machine is capable of processing steel, stainless steel, and alloy steel, making it suitable for a wide range of fastener manufacturing needs.Q: When is the best application for using this machine?

A: The machine is ideal for use in industrial environments where high-volume, precision bolt production is required, such as manufacturing plants, fastener production lines, and supplier facilities handling hex bolts and similar fasteners.Q: Where can I install and operate this machine?

A: Due to its substantial size (3200 mm x 1400 mm x 1800 mm) and weight (approximately 4200 kg), the machine should be installed in a spacious, well-ventilated industrial area with access to 380V, 3-phase power supply.Q: What is the production capacity and benefit of using this equipment?

A: The machine delivers a production cycle of approximately 40-90 pieces per minute, increasing operational efficiency and throughput for bolt manufacturers. It also features precision forming, resulting in consistently high-quality finished products.Q: What process is used for bolt formation in this machine?

A: The machine utilizes a two-mold, two-blow process to shape bolts from raw bars, ensuring accurate and repeatable results. Centralized automatic lubrication guarantees optimal machine performance and longevity.Q: What accessories and documentation are included with the machine?

A: Each unit comes with a tool kit and an instruction manual, assisting with installation, operation, and maintenance tasks for ease of use.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in इस्तेमाल किया मल्टी स्टेशन बोल्ट मेकिंग मशीन Category

CH0322 2 मोल्ड ब्लो बोल्ट मेकिंग मशीन

न्यूनतम आदेश मात्रा : 1

शर्त : इस्तेमाल किया गया

पावर : 220440 वोल्ट (v)

के लिए इस्तेमाल किया गया : औद्योगिक उद्देश्य

माप की इकाई : यूनिट/यूनिट्स

मूल्य की इकाई : यूनिट/यूनिट्स

Dongguan Wangketong मशीनरी उपकरण कं, Ltd

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें