DMU 210P-2009 फाà¤à¤µ à¤à¤à¥à¤¸à¤¿à¤¸ मशà¥à¤¨à¤¿à¤à¤ सà¥à¤à¤à¤°

DMU 210P-2009 फाà¤à¤µ à¤à¤à¥à¤¸à¤¿à¤¸ मशà¥à¤¨à¤¿à¤à¤ सà¥à¤à¤à¤° Specification

- क्षमता

- Large work envelope up to 2100 mm table diameter

- निर्माण वर्ष

- 2009

- आउटपुट

- High-precision multi-axis component machining

- वज़न

- Approximately 35,000 kg

- रंग

- White / Grey

- शर्त

- Used

- के लिए इस्तेमाल किया गया

- Precision metalworking, mold making, heavy component machining

- मशीन का प्रकार

- Five Axis Machining Center

- पावर

- Main spindle drive approx. 60 kW

- वोल्टेज

- 400 V, 50 Hz

- आयाम (एल* डब्ल्यू* एच)

- 8100 mm x 5500 mm x 3800 mm (approx.)

- फ़ीचर

- Simultaneous 5-axis machining, high rigidity, automatic tool changer, advanced CNC controls

- Machine Enclosure

- Fully enclosed for safety and cleanliness

- Coolant System

- High-pressure through-spindle cooling

- Y-Axis Travel

- 2100 mm

- Repeatability

- ±0.005 mm

- Max Table Load

- Up to 10,000 kg

- X-Axis Travel

- 1800 mm

- Spindle Speed Range

- Up to 8,000 rpm

- CNC Control System

- Heidenhain iTNC 530 or equivalent

- ATC (Automatic Tool Changer)

- 60 tools capacity

- Hydraulic Supply Requirement

- 40 bar (where applicable)

- Z-Axis Travel

- 1250 mm

- Table Size (Diameter)

- 2100 mm

- Chip Conveyor

- Integrated with external discharge

- Positioning Accuracy

- ±0.008 mm

- Air Supply Requirement

- 6 bar

DMU 210P-2009 फाà¤à¤µ à¤à¤à¥à¤¸à¤¿à¤¸ मशà¥à¤¨à¤¿à¤à¤ सà¥à¤à¤à¤° Trade Information

- Minimum Order Quantity

- 1 Unit

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- मुख्य निर्यात बाजार

- , , , , , , , ,

About DMU 210P-2009 फाà¤à¤µ à¤à¤à¥à¤¸à¤¿à¤¸ मशà¥à¤¨à¤¿à¤à¤ सà¥à¤à¤à¤°

Efficient Precision for Demanding Applications

The DMU 210P-2009 Five Axis Machining Center is engineered for simultaneous multi-axis machining, ideal for precision metalworking, mold manufacture, and heavy-duty component fabrication. Notable features include a fully enclosed structure for safety, integrated chip conveyor, and high-pressure coolant system. Compared to standard models, its supreme rigidity and automatic tool changer make it a popular solution for complex production environments requiring optimal consistency and versatility across a broad surface spectrum.

Certifications, Sample Policy, and Market Offer

Each DMU 210P-2009 conforms to industry-leading certifications for quality and precision. Interested parties can inquire about the sample policy and request detailed documentation before finalizing a proposal amount or asking price. The offer is primarily directed at the main domestic market but extends to international buyers through our distribution and export channels. This approach ensures that every proposal meets tailored business requirements, optimizing benefits for manufacturer, supplier, or trader alike.

FAQ's of DMU 210P-2009 Five Axis Machining Center:

Q: How does the DMU 210P-2009 enhance productivity in heavy component machining?

A: This machine's simultaneous five-axis capability, 60-tool automatic tool changer, and high spindle speed range up to 8,000 rpm enable efficient and precise machining for heavy components, reducing cycle times and improving output quality.Q: What industries benefit most from using the DMU 210P-2009 Five Axis Machining Center?

A: Industries involved in precision metalworking, mold making, and heavy component manufacturing gain optimal results from this machining center due to its large work envelope, high rigidity, and advanced CNC control system.Q: Where can I view or request a demonstration of the DMU 210P-2009?

A: You can contact the manufacturer, distributor, or exporter in China to schedule a viewing or demonstration, based on availability and sample policy details. Remote consultation is also available for international buyers.Q: What certifications does the DMU 210P-2009 comply with for quality assurance?

A: The DMU 210P-2009 adheres to leading international and domestic standards in machining center construction and performance, ensuring reliability and precision for industrial use.Q: How does the automatic tool changer contribute to machining efficiency?

A: Its 60-tool capacity allows swift tool transitions and uninterrupted operations, minimizing machine downtime while maximizing flexibility and efficiency across multiple machining tasks.Q: What is the process for obtaining an offer or proposal amount for the DMU 210P-2009?

A: Interested buyers are encouraged to submit their requirements, upon which the supplier or trader will provide a detailed offer or proposal amount that reflects the machine's specifications, certifications, and optional sample policy.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in पाँच अक्ष मशीनिंग केंद्र Category

MILLP 500UD फाइव एक्सिस मशीनिंग सेंटर

के लिए इस्तेमाल किया गया : Precision machining of complex components

शर्त : New

रंग : Standard Industrial Gray

माप की इकाई : Unit/Units

न्यूनतम आदेश मात्रा : 1

पावर : 22 kW main spindle

माकिनो S33-5XA

के लिए इस्तेमाल किया गया : Precision milling, drilling, tapping, and cutting metals

शर्त : Used

रंग : Makino standard grey/white

माप की इकाई : Unit/Units

न्यूनतम आदेश मात्रा : 1

पावर : 22 kW spindle motor

डीएमयू अल्ट्रासोनिक 10

के लिए इस्तेमाल किया गया : Industrial Component Cleaning

शर्त : New

रंग : Blue / Grey

माप की इकाई : Unit/Units

न्यूनतम आदेश मात्रा : 1

पावर : 2200 W

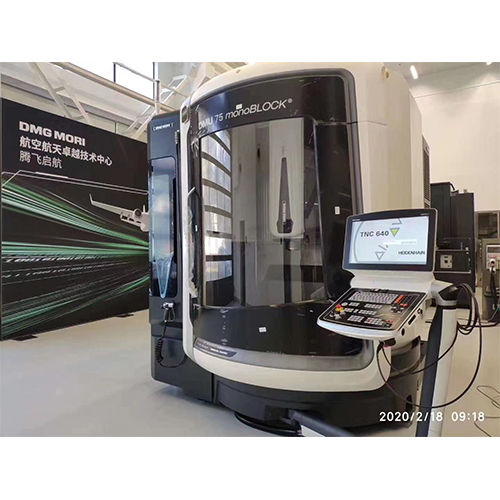

देमाजी DMU75 मोनो ब्लॉक फाइव एक्सिस मशीनिंग सेंटर

के लिए इस्तेमाल किया गया : Precision metal component machining

शर्त : New

रंग : White/Grey

माप की इकाई : Unit/Units

न्यूनतम आदेश मात्रा : 1

पावर : 38 kW

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें