DMC 160FD हाय-डिन फाà¤à¤µ à¤à¤à¥à¤¸à¤¿à¤¸ मशà¥à¤¨à¤¿à¤à¤ सà¥à¤à¤à¤°

DMC 160FD हाय-डिन फाà¤à¤µ à¤à¤à¥à¤¸à¤¿à¤¸ मशà¥à¤¨à¤¿à¤à¤ सà¥à¤à¤à¤° Specification

- क्षमता

- Workpiece up to 1,600 mm table diameter

- फ़ीचर

- Hi-Dyn, Fully simultaneous five-axis machining, FD Turn-Mill technology integration

- मशीन का प्रकार

- Five Axis Machining Center

- पावर

- Approx. 60 kW (main spindle)

- आउटपुट

- High speed and accuracy for aerospace, automotive, mold & die

- निर्माण वर्ष

- nan

- शर्त

- Used

- वोल्टेज

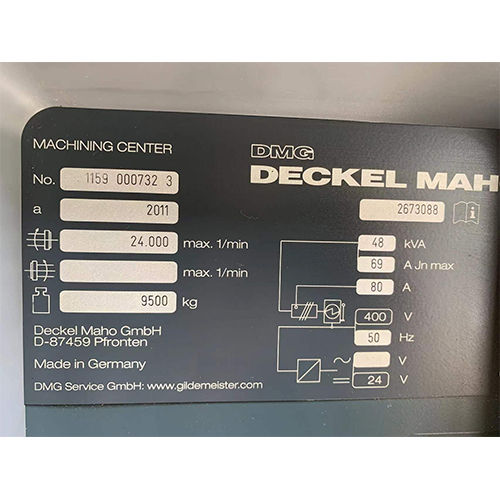

- 400 V, 50 Hz

- आयाम (एल* डब्ल्यू* एच)

- Approx. 8000 mm x 4800 mm x 3800 mm

- रंग

- White with grey and black panels

- वज़न

- Approx. 28,000 kg

- के लिए इस्तेमाल किया गया

- High precision and complex workpiece machining

- Environmental Compliance

- Meets CE and ISO machine tool standards

- Spindle Speed

- Up to 12,000 rpm

- Interface

- USB, Ethernet, and DNC compatibility

- Coolant System

- High-pressure coolant system integrated

- Control System

- Siemens 840D Solutionline

- Air Supply Requirement

- Minimum 6 bar pressure

- Chip Conveyor

- Included

- Turning Functionality

- Integrated turning with DirectDrive table

- Tool Magazine Capacity

- 60–120 tools (depending on configuration)

- Positioning Accuracy

- Up to 0.008 mm

- Linear Guideways

- High-rigidity linear guideways for all axes

- Rapid Traverse Rate

- Up to 60 m/min

- Table Load Capacity

- Up to 6,000 kg

- Noise Level

- < 80 dB(A) during operation

- Enclosure

- Fully enclosed for safety and chip containment

DMC 160FD हाय-डिन फाà¤à¤µ à¤à¤à¥à¤¸à¤¿à¤¸ मशà¥à¤¨à¤¿à¤à¤ सà¥à¤à¤à¤° Trade Information

- Minimum Order Quantity

- 1 Unit

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

- मुख्य निर्यात बाजार

- , , , , , , , ,

About DMC 160FD हाय-डिन फाà¤à¤µ à¤à¤à¥à¤¸à¤¿à¤¸ मशà¥à¤¨à¤¿à¤à¤ सà¥à¤à¤à¤°

Multifunctional Machine for High-End Precision Applications

The DMC 160FD Hi-Dyn Five Axis Machining Center is meticulously engineered for used high-precision, complex workpiece machining. Its standout Hi-Dyn technology, simultaneous five-axis machining, and integrated FD Turn-Mill capability allow for praiseworthy versatility. Noteworthy special features include a high-capacity tool magazine, direct drive table, and robust linear guideways. This system excels in demanding commercial environments such as aerospace, automotive manufacturing, and mold & die making, offering consistent performance and reliability for complex industrial tasks.

Export Markets, Policies & Price Estimate

Our DMC 160FD Hi-Dyn Five Axis Machining Center is primarily exported to leading international markets at the lowest price for its category. Request a sample policy and payment terms tailored to your needspriced competitively below the List price, with prompt estimates available for bulk or customized orders. Our distributor, exporter, and supplier network ensures secure and efficient transactions. Instant checkout is supported for select locations, ensuring global customers enjoy a seamless buying process and excellent after-sales support.

FAQs of DMC 160FD Hi-Dyn Five Axis Machining Center:

Q: How is the DMC 160FD Hi-Dyn Five Axis Machining Center used in manufacturing?

A: The machine is used for high-precision and complex machining of workpieces, especially in industries such as aerospace, automotive, and mold & die, due to its five-axis simultaneous machining and integrated turning capabilities.Q: What are the key benefits of the FD Turn-Mill technology integration?

A: FD Turn-Mill technology allows for both milling and turning operations on a single platform, improving workflow efficiency, reducing setup time, and enhancing overall precision across complex components.Q: Where is the DMC 160FD Hi-Dyn Five Axis Machining Center mainly exported?

A: This machining center is exported globally with a strong presence in established manufacturing hubs across Europe, North America, and Asia, particularly by manufacturers seeking superlative performance.Q: What payment terms and sample policies are available when purchasing this machine?

A: Payment terms are flexible and tailored per transaction, with detailed sample policies provided upon request. Pricing is competitively estimated around the lowest price bracket for its segment, with bulk estimate options available.Q: How does the high-pressure coolant system benefit the machining process?

A: The integrated high-pressure coolant system enhances tool life, improves chip removal, and maintains consistent machining quality, making it a champion feature for uninterrupted production.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in पाँच अक्ष मशीनिंग केंद्र Category

MILLP 500UD फाइव एक्सिस मशीनिंग सेंटर

वज़न : 4800 kg

आयाम (एल* डब्ल्यू* एच) : 2350 x 3200 x 2850 mm

के लिए इस्तेमाल किया गया : Precision machining of complex components

शर्त : New

रंग : Standard Industrial Gray

वोल्टेज : 380 V, 3 Phase

MAZAK VORTEX i-630V-6 क्षैतिज पांच-अक्ष मशीनिंग केंद्र

वज़न : Approx. 21,000 kg

आयाम (एल* डब्ल्यू* एच) : 5,094 mm × 3,048 mm × 3,378 mm

के लिए इस्तेमाल किया गया : Highprecision complex part machining; Aerospace, automotive, and industrial components

शर्त : New

रंग : Industrial Grey/White

वोल्टेज : 400V / 50Hz

DMU80 मोनोब्लॉक फाइव एक्सिस मशीनिंग सेंटर

वज़न : approx. 13,000 kg

आयाम (एल* डब्ल्यू* एच) : 4,800 mm x 3,300 mm x 2,800 mm

के लिए इस्तेमाल किया गया : Precision 5axis milling and machining

शर्त : Used

रंग : White / Grey

वोल्टेज : 400 V

ओकुमा क्षैतिज मशीनिंग केंद्र MILLAC-800VH

वज़न : Approx. 18000 kg

आयाम (एल* डब्ल्यू* एच) : 4300 mm x 2600 mm x 3000 mm

के लिए इस्तेमाल किया गया : High precision metal cutting and milling applications

शर्त : Used

रंग : Standard Grey

वोल्टेज : 380415V (3 Phase)

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें